Protective clothing plays a pivotal role in ensuring the safety and health of workers across various industries. Disposable coveralls, a crucial component of personal protective equipment (PPE), offer a barrier against a wide range of hazards, from chemical spills to biological contaminants. This comprehensive guide is designed to navigate businesses through the myriad options available, ensuring the selection of the right types of disposable coveralls tailored to their specific needs.

Introduction to Disposable Coveralls

The Importance of Protective Clothing

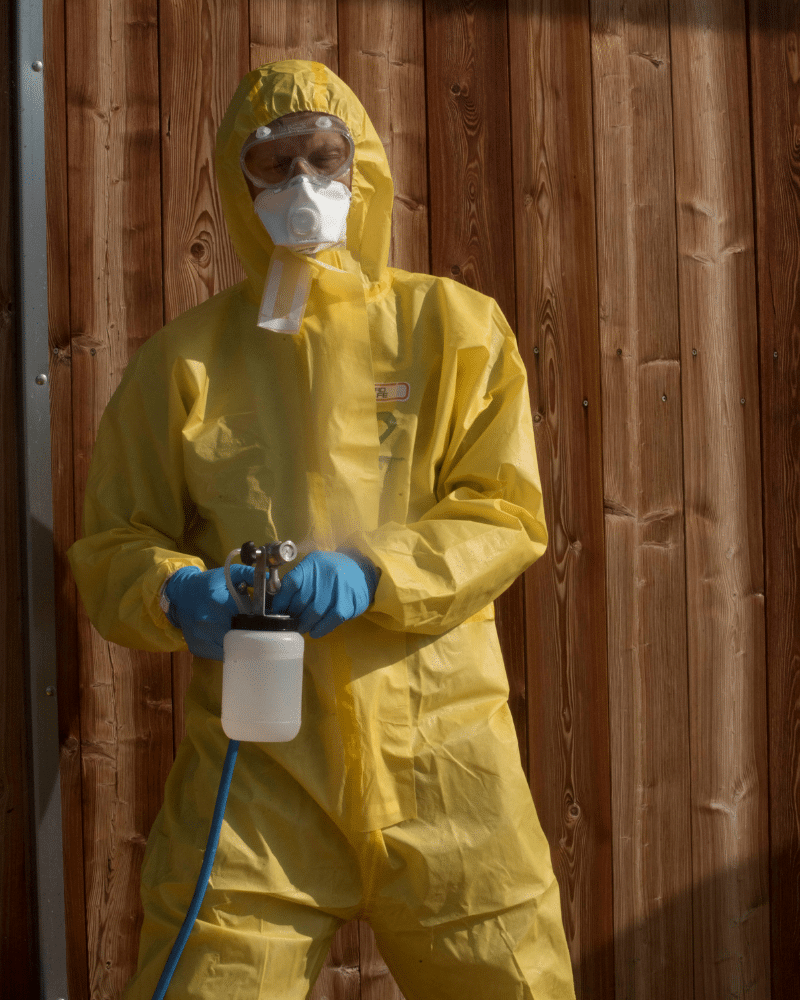

Protective clothing safeguards workers against potentially life-threatening situations. It’s more than just a layer of fabric; it’s a critical safety measure that, when properly selected and used, can prevent accidents and save lives. Disposable coveralls serve as the first line of defense, offering protection against various hazards that can be encountered in the workplace.

Overview of Disposable Coveralls

Disposable coveralls are designed to protect against a range of substances, including dust, liquids, chemicals, and other hazardous materials. They are made from different materials, each suited to specific types of protection, and are used once before being safely disposed of. This not only ensures maximum protection for each use but also helps in maintaining hygiene standards, especially crucial in industries dealing with infectious diseases or toxic substances.

Types of Disposable Coveralls

Polypropylene Coveralls

Polypropylene coveralls are lightweight and offer protection against dry particulates and light liquid splashes. They are ideal for non-hazardous environments where a basic level of protection is sufficient. Their breathability makes them comfortable for extended wear, especially in warm conditions.

Non-Woven Material Coveralls

Coveralls made from non-woven material provide a balance between protection, durability, and comfort. They are suitable for a variety of applications, from industrial cleaning to handling biologically contaminated particles. Non-woven coveralls are designed to offer protection against both dry and wet hazards, making them versatile options for many businesses.

Specialized Protective Coveralls

Chemical Protection: For industries dealing with hazardous chemicals, coveralls that can withstand compressed fluids and offer protection against chemical splashes are essential. Materials such as Tyvek provide excellent protection while maintaining a high level of comfort.

Biological Hazards: In healthcare settings or industries exposed to biologically contaminated particles, coveralls that offer a barrier against infectious diseases are crucial. Features like elastic wrists, boot covers, and hooded designs ensure comprehensive protection.

Features of High-Quality Disposable Coveralls

Hood and Elastic Wrists

A well-designed disposable coverall will include features like a hood and elastic wrists to ensure a secure fit, minimizing exposure to harmful substances. These features are vital for workers in environments where they are exposed to fine particles or splashes, as they provide an added layer of protection by sealing off potential entry points for hazardous materials.

Welded Seams and Extra Protection

High-quality coveralls often feature welded seams, which offer superior strength and durability compared to traditional stitching. This is particularly important in providing excellent protection against liquid penetration, ensuring that workers are kept safe from light spray, liquid splashes, and other forms of moisture. For tasks that involve exposure to hazardous substances, coveralls with extra protection in critical areas, such as double layers or reinforced panels, can offer an added assurance of safety.

Breathable Materials and Comfort

Comfort is an essential factor in protective clothing, as it directly impacts the wearer’s ability to work efficiently and safely. Disposable coveralls made from breathable materials help to reduce heat stress and improve overall comfort during long periods of wear. This not only enhances worker satisfaction but also promotes compliance with safety protocols, as workers are more likely to wear protective clothing that is comfortable.

Selecting the Right Disposable Coveralls

Assessing Workplace Hazards

The first step in choosing the right disposable coveralls is to assess the specific hazards present in the workplace. This could range from exposure to dry particles and asbestos in construction sites to chemical splashes in industrial cleaning jobs. Understanding the nature of the hazards will guide businesses in selecting coveralls with the appropriate level of protection.

Material and Design Considerations

The material and design of disposable coveralls are crucial factors in their effectiveness. For instance, polypropylene coveralls are suitable for light-duty tasks, while materials like Tyvek are preferred for environments requiring higher levels of protection against chemicals or biological hazards. The design of the coverall, including features such as hoods, elastic wrists, and boot covers, should align with the specific needs of the task at hand.

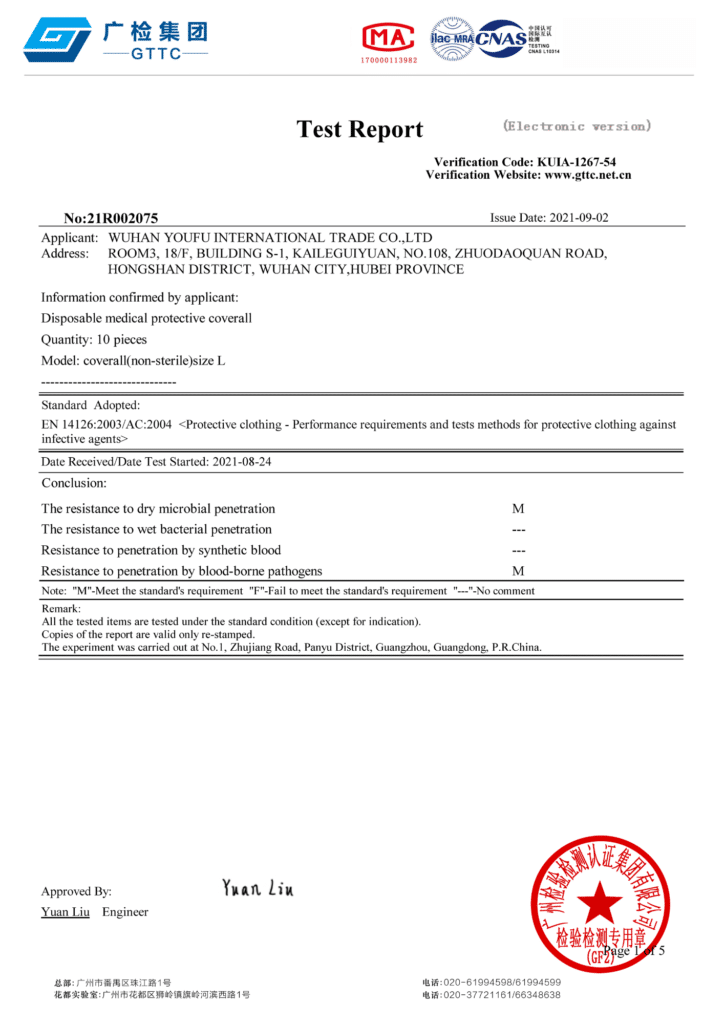

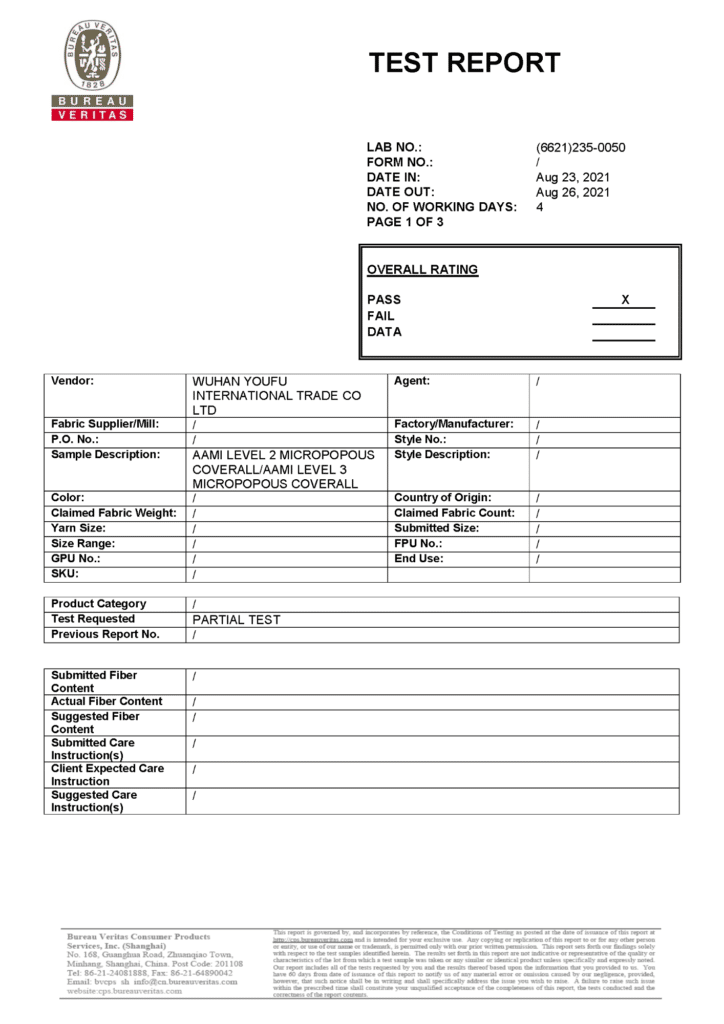

Compliance with Standards (EN 14126)

Compliance with safety standards is a critical consideration when selecting disposable coveralls. EN 14126, for example, specifies requirements and test methods for protective clothing against infectious agents. Businesses should ensure that the coveralls they choose meet or exceed the relevant standards for their industry, providing their workers with the highest level of protection possible.

Safety Standards and Certifications

Understanding EN 14126

EN 14126 is a key standard for protective clothing in industries where workers are exposed to infectious agents. This standard ensures that the fabric and design of the coveralls provide effective protection against biological hazards. Businesses should look for coveralls certified to meet EN 14126 as part of their selection criteria, ensuring comprehensive protection for their workers.

Other Relevant Certifications

In addition to EN 14126, there are other relevant certifications and standards that may apply, depending on the industry and the specific hazards involved. For example, certifications related to chemical protection or fire resistance might be necessary for certain roles. Understanding and adhering to these standards is essential for ensuring workplace safety and compliance with regulatory requirements.

Practical Considerations for Businesses

Economical Protection Strategies

While safety is the paramount concern, businesses must also consider the cost-effectiveness of their protective clothing choices. Disposable coveralls offer an economical solution by providing effective protection without the need for laundering or extensive maintenance. However, selecting the right type of coverall for the specific needs of the task can further optimize costs without compromising safety.

Training and Proper Use of PPE

Proper training in the use of PPE is crucial for ensuring that workers are protected. This includes instruction on correctly donning and doffing coveralls, understanding the limitations of their protective gear, and recognizing when it is necessary to replace worn or damaged equipment. Regular training sessions can help reinforce the importance of PPE and ensure that all workers are up to date on best practices.

Maintenance and Disposal

Although disposable coveralls are designed for single-use, proper disposal procedures are essential to prevent environmental contamination or the spread of hazardous substances. Businesses should establish protocols for the safe disposal of used coveralls, including segregation of contaminated clothing and compliance with local waste management regulations.

Industry-Specific Recommendations

Industrial Cleaning and Hazardous Materials

For industries involved in industrial cleaning or handling hazardous materials, coveralls that offer robust protection against chemical splashes and biological hazards are essential. Materials with high tensile strength and resistance to a wide range of chemicals, along with features like gas tightness and welded seams, are ideal for these settings.

Healthcare and Biological Risks

In healthcare settings, where workers are exposed to infectious agents, disposable coveralls that meet EN 14126 standards provide essential protection. Features such as elastic wrists, hooded designs, and materials that offer a barrier against biologically contaminated particles are crucial for preventing the spread of infectious diseases.

Construction and Asbestos Handling

In construction and asbestos removal, durable coveralls resistant to abrasion and tearing, while providing protection against dry particles and asbestos fibers, are necessary. Coveralls with a high level of breathability, along with adequate protective features like elastic wrists and boot covers, ensure that workers are shielded from asbestos and other hazardous dust particles. The selection of coveralls with materials that prevent the penetration of asbestos fibers is critical for minimizing health risks associated with long-term exposure.

Future Trends in Disposable Protective Clothing

Technological Advancements

The field of protective clothing is witnessing continuous technological advancements aimed at enhancing safety, comfort, and environmental sustainability. Innovations in materials science are producing more durable, lightweight, and protective fabrics, offering improved resistance to hazardous substances while ensuring wearer comfort. Future trends may include the integration of smart technologies that can monitor environmental hazards in real time and alert wearers to potential dangers.

Sustainability in Disposable Apparel

As environmental awareness increases, the demand for sustainable options in disposable protective clothing is growing. Manufacturers are exploring eco-friendly materials and production processes that reduce the environmental impact of disposable coveralls. Biodegradable materials, recycling programs, and initiatives aimed at reducing waste in the production of disposable apparel are becoming more prevalent, reflecting a commitment to sustainability without compromising on safety.

Conclusion

Choosing the right types of disposable coveralls for your industry is a critical decision that impacts the safety and well-being of workers. By understanding the specific hazards present in the workplace, considering material and design features, and ensuring compliance with relevant safety standards, businesses can select protective clothing that offers effective protection. As technologies and standards evolve, staying informed about the latest developments in protective clothing will enable businesses to continue providing their workers with the best possible protection.

FAQs

1.What is the significance of EN 14126 certification for disposable coveralls?

EN 14126 certification indicates that disposable coveralls meet specific requirements and test methods for protective clothing against infectious agents, offering assurance of their effectiveness in preventing biological contamination.

2.How often should disposable coveralls be replaced?

Disposable coveralls should be replaced after each use or when they become damaged, contaminated, or breached. It’s crucial to adhere to the manufacturer’s guidelines and industry best practices for the disposal and replacement of protective clothing.

3.Can disposable coveralls be recycled?

Recycling options depend on the materials used in the coveralls and the nature of any contamination. While some components may be recyclable, contaminated coveralls must be disposed of according to hazardous waste regulations. It’s important to consult local waste management policies and recycling programs.

4.Are there breathable options available for disposable coveralls?

Yes, there are breathable options made from materials that allow air and moisture to pass through, reducing heat stress and improving comfort for the wearer. These options are particularly suitable for warm environments or extended periods of wear.

5.How can businesses ensure the proper fit of disposable coveralls for their workers?

Businesses should consider the size and body shapes of their workforce when selecting coveralls. Many manufacturers offer a range of sizes and designs to accommodate different body types. Additionally, adjustable features such as elastic wrists, waists, and ankles can help ensure a secure and comfortable fit.