Keeping food safe is super important. The clothes workers wear in the food industry play a big part in this. Using the wrong clothes can lead to germs spreading, which is bad for everyone. That’s why many food places now use nonwoven work clothes. These special clothes help stop cross-contamination and meet important food factory hygiene protocols. Let’s explore why this disposable protective workwear is a smart choice for food safety.

The Problem with Old-Style Work Clothes

Regular clothes, like cotton shirts or uniforms, might seem okay, but they have downsides in food areas.

- Germs Can Hide: Woven fabrics have tiny spaces where germs, dust, and food bits can get trapped. This makes it easier for pathogens to stick around.

- Shedding Tiny Bits: Regular clothes can shed small fibers, like lint. These bits can fall into food, causing problems. Good particle-shedding control is needed.

- Washing Issues: Washing reusable uniforms needs careful handling to make sure all germs are gone. If not done right, germs can survive and spread. Industrial laundry alternatives, like using disposable clothes, avoid this risk.

Using traditional textiles makes it harder to keep everything perfectly clean and safe.

What Makes Nonwoven Fabrics Special?

Nonwoven fabrics are different. They are not made by weaving threads. Instead, fibers are bonded together using heat, chemicals, or pressure. This creates a unique material perfect for hygienic food processing uniforms.

- How They’re Made: Common materials include Polypropylene nonwoven (often called PP) and SMS (Spunbond-Meltblown-Spunbond) fabric. SMS is known for having layers that provide a good barrier while still letting air through.

- Key Differences: Nonwovens offer advantages over regular cloth.

Here’s a quick look:

| Характеристика | Nonwoven Fabrics | Traditional Clothes (Cotton/Polyester) |

|---|---|---|

| Little Bits (Lint) | Low lint / Non-linting | Can shed fibers easily |

| Keeping Liquids Out | Good Liquid-repellent properties | Can soak up liquids |

| Safety Rules | Helps meet FDA & HACCP needs | May not meet strict rules |

These features make nonwovens ideal based on nonwoven fabric safety standards.

Big Benefits of Nonwoven Workwear for Food Safety

Choosing nonwoven work clothes brings several key benefits to food making:

- Better Hygiene: Because they are often disposable protective workwear, workers use them once and then throw them away. This greatly reduces the chance of carrying germs from one place or batch to another. It’s top-notch cross-contamination prevention gear.

- Great Barrier: Materials like SMS fabric act as strong microbial barrier fabrics. They help block tiny germs, liquids, and allergens. This keeps both the food and the worker safer.

- Comfort for Workers: Many nonwovens, especially SMS, are surprisingly breathable disposable clothing. This means workers don’t get too hot. Comfortable workers are more likely to wear their gear correctly all day long. They are often lightweight protective gear.

- Saves Money: While buying disposable items might seem costly, you save money on laundry (water, energy, soap). You also don’t need to repair or replace worn-out uniforms as often. This makes them a cost-effective industrial laundry alternative.

- Helps Meet Rules: Using proper nonwoven gear helps companies follow important food safety rules set by groups like the FDA and systems like HACCP.

These benefits make nonwovens a smart choice for meeting food-grade PPE requirements and GMP (Good Manufacturing Practices) workwear needs.

Meeting Safety Rules

In the food world, following safety rules is not optional. Nonwoven work clothes are designed to help businesses comply.

- Key Standards: Companies need to follow rules like:

- HACCP (Hazard Analysis Critical Control Point): This system identifies risks in food production. HACCP-compliant uniforms are essential PPE.

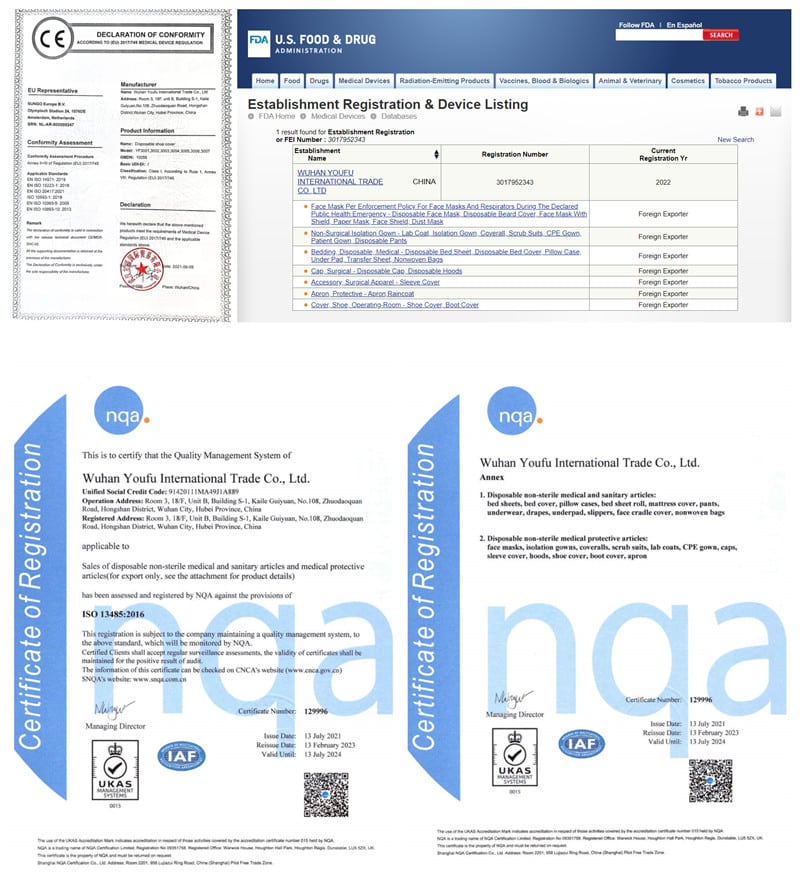

- FDA (U.S. Food and Drug Administration): Has rules about materials that can safely touch food (food contact materials). Look for FDA-compliant food industry clothing.

- GMP (Good Manufacturing Practices): These are general rules for keeping production clean and safe, including what workers wear.

- How Nonwovens Help:

- Their barrier properties prevent workers from contaminating food.

- Their low-linting nature stops fibers from getting into products.

- Being disposable ensures a fresh, clean start, supporting hygiene protocols.

Using the right nonwoven work clothes shows a commitment to safety and makes passing inspections easier.

Picking the Right Nonwoven Gear

Different jobs in a food facility need different types of protection. Choosing the right nonwoven gear is important.

- Match the Task:

- Комбинезоны: For full body protection, especially in sensitive areas, disposable protective coveralls with hood are a good option. Basic polypropylene coveralls work well for general tasks.

- Aprons: To protect clothes from splashes, choose aprons. A simple Disposable non woven apron is great for light tasks, while a Одноразовый пластиковый фартук для пищевой промышленности offers more robust, waterproof protection.

- Lab Coats/Smocks: For visitors or workers needing light protection, disposable smocks or lab coats are suitable.

- Hairnets & Beard Covers: Essential for keeping hair contained. Options include medical bouffant clip cap for nurse and doctor and beard snoods.

- Shoe Covers: Keep floor germs from spreading with disposable shoe booties. Choose non-skid options for safety.

- Consider the Material:

- PP (Polypropylene): Good for dry areas, lightweight, breathable.

- SMS (Spunbond-Meltblown-Spunbond): Offers a better barrier against liquids and particles while still being breathable. Good for many situations.

- PE Coated PP/Microporous: Provide high liquid protection, great for wet environments.

Think about the specific risks (food spills, dust, germs) in each area when selecting gear.

New Ideas for Sustainability

Many people are thinking about the planet. The good news is that there are efforts to make disposable clothing more eco-friendly.

- Better Materials: Research is ongoing into materials that break down more easily (biodegradable nonwovens) or come from renewable sources.

- Recycling Programs: Some places are setting up programs to collect and recycle certain types of used nonwoven gear, turning waste into something useful.

While disposables offer huge hygiene benefits, the industry is working on ways to reduce their environmental impact.

Conclusion: Nonwovens Really Matter

In the food industry, keeping things clean is everything. Nonwoven work clothes play a vital role.

- They provide a better barrier against germs and dirt than regular clothes.

- They help businesses meet safety standards например, HACCP, FDA, и GMP.

- They are often more comfortable for workers.

- Their Одноразовые nature offers unmatched hygiene benefits and can be cost-effective.

Choosing the right nonwoven work clothes for the food industry – from coveralls and aprons to hairnets and shoe covers – is a critical step in protecting food, workers, and customers. They are essential tools for modern food safety.