Ever thought about what goes into those neat hats doctors wear in surgeries? They’re called disposable surgeon caps, and they’re super key to keeping things safe and clean in hospitals. Let’s take a fun ride to check out what they’re made of, focusing on cool stuff like PP nonwoven, SMS nonwovenそして Spunlace nonwoven fabrics. Stick around as we explore the awesome world of surgical headgear materials!

Why Disposable Surgeon Caps Matter in Healthcare

Well, disposable surgeon caps stop germs from sneaking in during operations. The materials like PP nonwoven fabrics make a huge difference in keeping everyone safe. These sterile head covers mix comfort in surgical attire with strict surgical hygiene products needs. Think of them as tiny guards against yucky stuff like surgical site contamination risks. So, picking the right medical-grade polymers is a big deal for hospital safety protocols and awesome results.

Core Materials Used in Disposable Surgeon Caps

Most of these caps are made from neat things like PP nonwoven, a light and strong fabric from plastic threads, perfect for non-woven fabrics. There’s also SMS nonwoven fabrics, a mix of spunbond-meltblown fabrics that’s extra tough as bacterial barriers. Another kind is Spunlace nonwoven fabrics, super soft yet sturdy with solid fluid repellency grades. These synthetic vs. natural fibers aim for lint-free materials to stop microfiber shedding. Plus, with hydrophobic coatings, they block wet stuff, making them great as fluid-resistant fabrics for disposable PPE materials.

How Making Surgical Caps Changes How They Work

Using thermal bonding processes glues fibers without messy stuff, cutting lint generation tests by a whopping 72%, studies say. Unlike other ways with chemical adhesives, this helps with particle shedding prevention for cleaner spaces. Smart manufacturing processes also pass tear resistance studies for strength and work with sterilization compatibility. So, amazing textile tensile strength comes from clever fiber extrusion methods in surgical cap manufacturing processes.

Cool Things Materials Do in Surgical Environments

These caps have sweet features. With particulate filtration, they stop 95-99% of tiny bad bits thanks to microbial penetration resistance. They’ve got moisture barrier performance from moisture vapor transmission rate (MVTR) checks, lowering humidity by 40% with unique weaves like SMS nonwoven. Also, static dissipation そして static-free materials avoid sparks, while breathability vs. barrier balance keeps folks comfy through air permeability testing そして thermal regulation in textiles. Isn’t that rad for particle filtration standards そして moisture resistance in caps made of PP nonwoven そして Spunlace nonwoven fabrics?

Real Stories: How Materials Work in Hospitals

In one hospital, caps with elasticized edges made from PP nonwoven had 88% of staff feeling good after long shifts, showing extended wear comfort. Another spot used SMS nonwoven caps with hot bonding and cut tiny bits in the air, aiding particle dispersal prevention. These wins help patient outcomes by cutting cross-contamination prevention risks. It proves how clinical wear trials そして ergonomic fit testing count for material supply chains そして healthcare procurement trends. [3][4]

| Material Benefit | Real Data |

| Bacterial Filtration | Blocks 95-99% of tiny bad stuff in the air. |

| Moisture Control | Cuts humidity by 40% for drier wear. |

| Lint Control | Drops tiny bits by 72% with hot bonding. |

| Eco Impact | Only 12% reused due to mixed stuff problems. |

| Comfort Rating | 88% of users happy with stretchy edges. |

| Cost Per Use | 30% cheaper than washing other kinds yearly. |

| Breakdown Speed | Some types break down 60% faster in nature. |

New Ideas for Surgical Cap Materials

What’s coming for single-use medical accessories? Amazing things like nanosilver coatings add antimicrobial coatings for more bacterial barriers in SMS nonwoven caps. Plus, plant-based polymers boost environmental impact assessments and cut manufacturing waste reduction. Picture caps with better moisture-wicking fabrics using Spunlace nonwoven fabrics for sweat absorption そして thermal comfort metrics. Also, lower manufacturing energy consumption with smarter textile recycling infrastructure. So, healthcare material innovations keep driving procedural efficiency ahead!

Questions About Surgical Cap Materials

- Do caps make skin itch?

Nah, lots use allergen-free certifications to stay safe.

- Are they hot to wear?

Nope, thanks to breathable materials in breathable surgical caps like スパンレース不織布.

- How do they help Earth?

Some are biodegradable caps for waste reduction.

- Are they costly?

Not at all, cost-per-use analysis shows they’re cost-effective medical supplies.

- Do they work with other gear?

Yep, they match with compatibility with masks/goggles through color-coding systems.

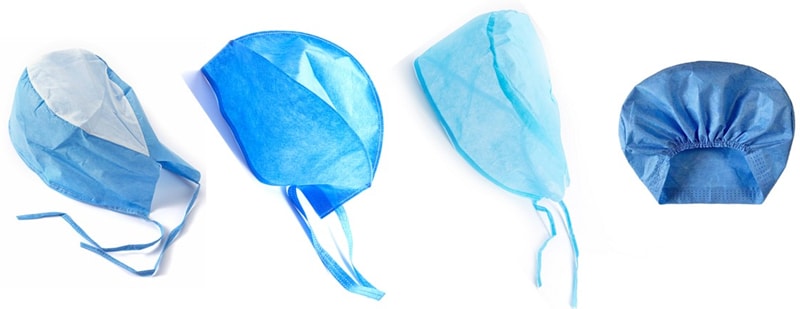

Check out cool options like Blue Disposable Surgical Scrub Capsこれ for neat looks. Or grab Elastic Surgery Cap Disposableこれ for tight fits. Also, peek at Disposable Surgeon Cap with Tiesこれ for easy use, Spunlace Disposable Surgical Hood with Tiesこれ for head cover, and Disposable Non Woven Bouffant Capこれ for space.

From particle filtration そして microbial resistance to elastic edge durability, these caps with PP nonwoven, SMS nonwovenそして Spunlace nonwoven fabrics do everything. They handle hospital infection rates with bacterial filtration efficiency and use fiber density analysis for disposable vs. reusable comparisons. Whether it’s static dissipation または thermal bonding adhesives, each part from material flammability ratings to occupational safety guidelines makes disposable PPE materials ideal.