Cadaver pouches, also known as body bags or mortuary pouches, play a critical role in the respectful and safe handling of deceased bodies in various settings, including hospitals, morgues, and disaster situations. Companies such as Wuhan Youfu work to produce high-quality cadaver pouches using advanced materials and manufacturing techniques.

Overview of Common Materials Used in Cadaver Pouches

The primary materials used in the manufacture of cadaver pouches include PEVA, PVC, PE, and PP nonwoven. These materials are chosen for their strength, durability, and safety properties, ensuring the pouches can effectively contain and transport bodies while minimizing the risk of biohazard exposure.

Polyethylene Vinyl Acetate (PEVA)

PEVA is a vinyl made without chlorine, making it environmentally friendly and less harmful to humans. It is non-toxic and has excellent clarity, flexibility, and resistance to UV radiation and water, making it a suitable material for cadaver pouches.

Polyvinyl Chloride (PVC)

PVC is a commonly used plastic material known for its durability and resistance to environmental conditions. It is a cost-effective choice for cadaver pouches, providing excellent barrier properties and mechanical strength.

Polyéthylène (PE)

PE is another popular choice for cadaver pouches due to its flexibility, chemical resistance, and impermeability. It’s lightweight and easy to manipulate, making it ideal for the manufacture of body bags.

Polypropylene Nonwoven (PP Nonwoven)

PP nonwoven is a type of fabric made from thermoplastic polymers. It’s light, breathable, and resistant to moisture, chemicals, and UV degradation. Its non-allergenic and non-toxic properties make it safe for use in cadaver pouches.

The Manufacturing Process

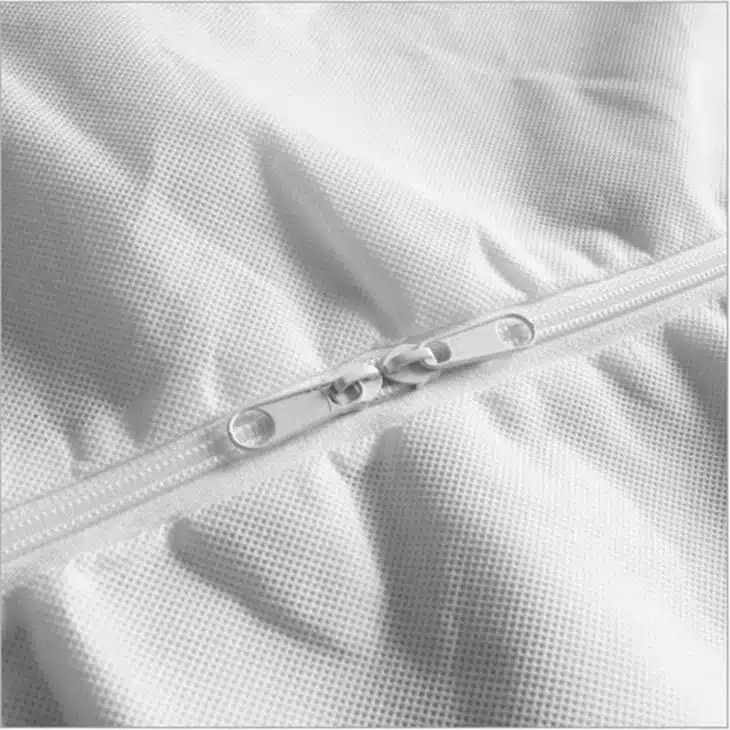

The manufacturing process of cadaver pouches involves careful selection of materials, precise cutting and shaping, and rigorous quality control. Companies like Wuhan Youfu utilize advanced manufacturing techniques to ensure each pouch meets the highest standards of quality and safety, the join parts are ultrasonic heat sealing, and zippers are sewn with flat sewing machine for high level durability.

Innovations and Developments in Material Use

The field of cadaver pouch manufacturing continues to evolve with new material innovations. These advancements aim to improve the functionality, safety, and environmental impact of cadaver pouches, ensuring they meet the changing needs of the healthcare and mortuary sectors.

Conclusion

Understanding the materials and manufacturing processes behind cadaver pouches is crucial in selecting the right products for specific needs. Companies like Wuhan Youfu are dedicated to providing top-quality, safe, and respectful solutions for the handling of deceased bodies.

FAQs :

- What materials are commonly used in the manufacture of cadaver pouches?

- The most common materials are PEVA, PVC, PE, and PP nonwoven.

- Why is PEVA used in cadaver pouches?

- PEVA is used because it is non-toxic, resistant to UV radiation and water, and environmentally friendly.

- What role does PP nonwoven play in cadaver pouches?

- PP nonwoven is light, breathable, and resistant to moisture, chemicals, and UV degradation, making it ideal for cadaver pouches.

- How are cadaver pouches manufactured?

- The process involves careful selection of materials, precise cutting and shaping, and rigorous quality control to ensure safety and quality.

- What are the recent advancements in cadaver pouch material use?

- Recent advancements focus on improving functionality, safety, and environmental impact of cadaver pouches, including the use of new materials and improved manufacturing techniques.