Here’s a simple look at how disposable EVA slippers are made:

- Getting the Material Ready: The main ingredient is EVA (Ethylene Vinyl Acetate), which comes as small plastic beads. This material is chosen because it’s light, bendy, strong, and doesn’t soak up water. Other things like color powder are added to get the right look and feel.

- Mixing: All the ingredients (EVA beads and additives) are mixed together very well so the final slippers are consistent.

- Making Sheets: The mix is melted down and pushed through a machine to form flat sheets of the right thickness. Think of it like rolling out dough.

- Cooling and Cutting: These warm sheets are cooled down. Once cool, they might be cut into smaller, more manageable sizes for the next step.

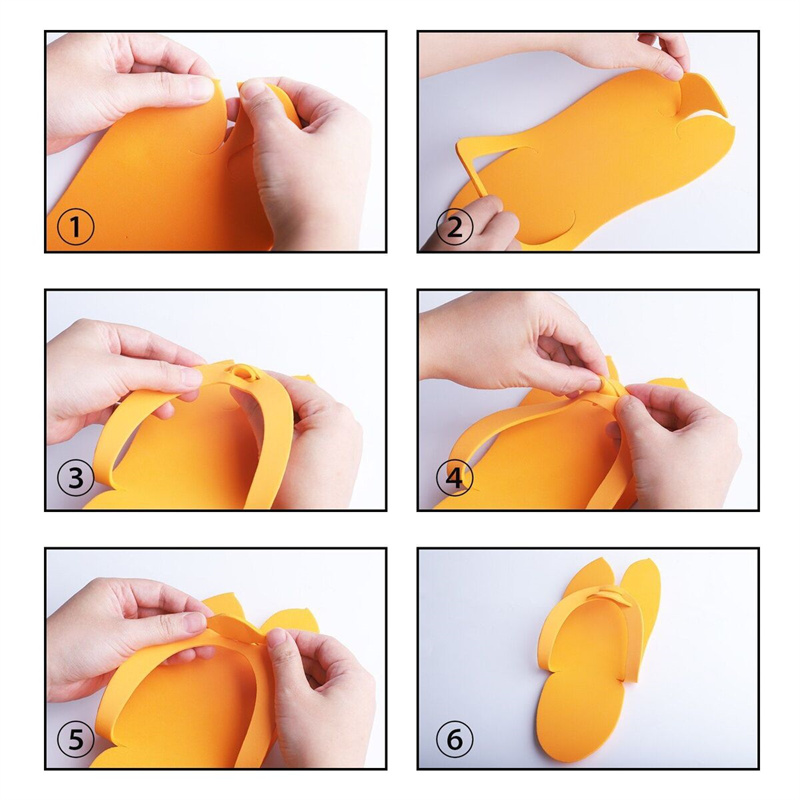

- Cutting Out Slipper Shapes: Using special cutting tools shaped like the slippers (called dies), the factory cuts out the sole (the bottom part) and the straps from the EVA sheets. For very simple designs, the whole slipper might be cut out in one go. For styles like disposable flip flops, the straps and soles are often cut separately.

- Putting Them Together (Assembly): If the straps were cut separately, they are now attached to the soles. This is usually done with special glue or by using heat to stick them together firmly.

- Adding Grip: To stop slipping, a pattern is often put on the bottom of the sole. This texture can be added when the sheets are first made or during the cutting step. These are helpful features for products like foam pedicure slippers.

- Checking Quality: Workers look over the finished slippers to make sure they look right, are the correct size, and are put together properly. They check for any mistakes.

- Embalagem: The finished disposable spa slippers are usually packed in pairs, often in plastic bags to keep them clean. Then, lots of pairs are packed into bigger boxes to be sent to places like spas, hotels, or nail salons. They are convenient alternatives to standard disposable sandals for showers.

Adding Logos (Optional): Sometimes, companies want their name or logo printed on the slippers. This is done using special printing methods that work well on EVA material.