- What are disposable hotel slippers?

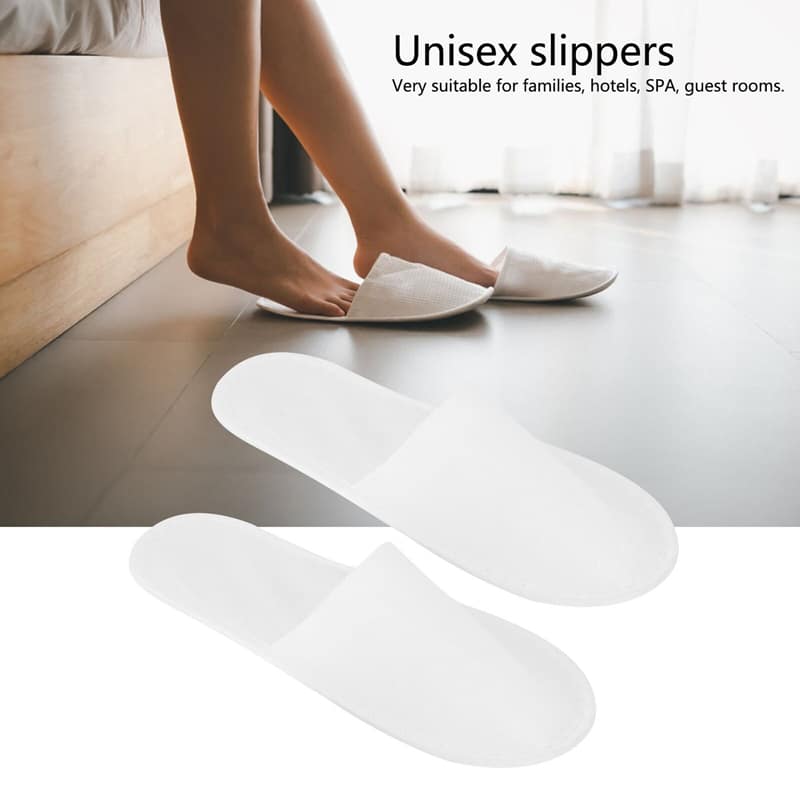

- Disposable hotel slippers are soft shoes for one time use. They are clean and light. Hotels give them to guests. Spas and salons use them too. You wear them in rooms, baths, pools, or spa areas. They help keep feet clean. They help floors clean too. They are easy to pack. They are easy to store. They come in pairs. They may be open toe ou closed toe. They may be white or other light colors. Use once. Then toss. It is simple. It feels fresh. It feels safe.

- Common types and styles

- There are many kinds of disposable hotel slippers. You can pick open toe disposable hotel slippers for breath. You can pick closed toe disposable hotel slippers for more cover. Some are Chinelo descartável em tecido não tecido for light wear. Some are Disposable EVA slippers for SPA for soft steps. For guests, there are Closed toe disposable slippers for guests. For spa days, there are disposable spa slippers e Disposable Pedicure slippers EVA foam. For showers, there are disposable sandals shower slippers. For kids, there are chinelos descartáveis giros para crianças. One size may fit most. Some are small. Some are big.

- Materials and parts

- Disposable hotel slippers use soft top fabric. Many use non woven or soft cloth. The foot bed can feel plush. The sole can be firm. Some soles use EVA foam for comfort. Some soles have dots for anti slip. This helps on wet floors. The heel can be thin or thick. Thick soles feel softer. Thin soles are light and low cost. Stitching should be smooth. Edges should be neat. Wraps can be a clear bag. A paper band can hold the pair. A clean pack keeps the pair fresh.

- How to choose the right pair

- Think about where you will use disposable hotel slippers. For rooms and beds, choose closed toe. For hot days or spa steam, choose open toe. For showers, choose disposable sandals shower slippers with grip. For nail care, choose Disposable Pedicure slippers EVA foam. For spa sets, choose disposable spa slippers ou Disposable EVA slippers for SPA. For VIP rooms, pick thicker soles. For short stays, pick light ones. Make sure the sole is anti slip. Check size. Keep a few kid sizes, like chinelos descartáveis giros para crianças.

- Use, pack, and care tips

- Keep disposable hotel slippers in a dry place. Hand them to each guest in a clean pack. Put a pair by the bed or in the bath. Use on tile, wood, or carpet. Use for spa, pool, or nail care too. After use, toss them in the right bin. Train staff to place one pair per stay. For wet areas, pick open toe or shower styles. For cool rooms, pick closed toe. Restock by floor and by size. Light pairs save space. Thick pairs add comfort. Both help guests feel neat, calm, and cared for.