Big kitchens run fast. Food moves. Hands work nonstop. In this world, guantes desechables are a must. The goal is safe food and smart costs. This guide shows economical sourcing of disposable gloves for large-scale cooking operations. It uses simple steps you can follow today.

Why disposable gloves matter in large kitchens

Large-scale cooking operations have many stations, many tasks, and many people. Gloves help you:

- Protect food from germs and oils on skin

- Protect hands from heat, spices, oils, and dyes

- Speed workflow with quick changes between tasks

- Build trust with a clean, pro look

But you need the right glove at the right price. That is where economical sourcing comes in.

What “economical sourcing” means

Economical sourcing is not just the lowest price. It is the best value across the whole job. It balances:

- Cost per pair

- Ajuste y comodidad

- Durability during tasks

- Fast delivery and steady stock

- Low waste and easy change

Good sourcing cuts hidden costs like breaks, slowdowns, and food waste.

Map your use by station

Start with a clear map of glove use. Walk your line and list the tasks.

- Prep: raw meat, fish, veg trim, spice rubs

- Cook line: grill, fry, bake, sauce, plate

- Cold: salad, dessert, deli

- Pack-out: portion, seal, label

- Cleaning: wipe, wash, trash

Now note glove needs for each:

- Light duty for dry prep and plate up

- Medium duty for wet or oily tasks

- High turnover at raw-to-ready change points

This map is your base for economical sourcing of disposable gloves for large-scale cooking operations.

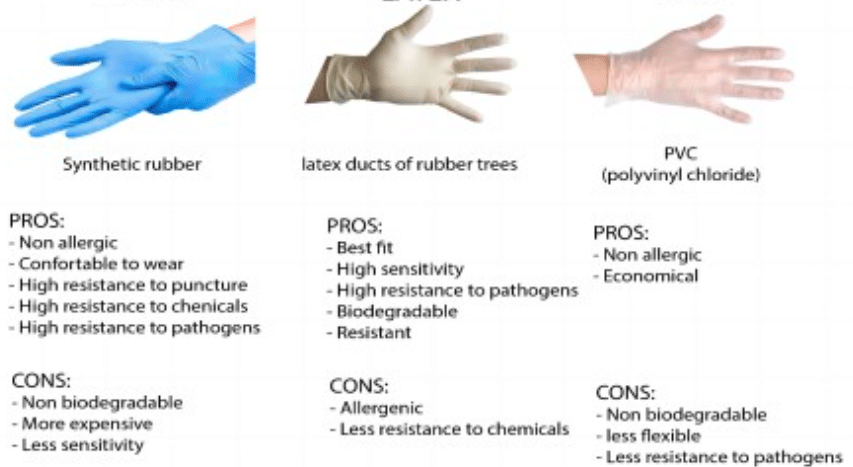

Choose glove materials by task

Pick materials that match the work and budget.

- CPE/PE (light duty)

- Good for short, high-change tasks

- Lower cost per pair

- Great for portion and pack-out

- See: Guante de plástico desechable CPE for quick service lines

- General food-handling gloves

- Smooth, easy on/off

- Good for light to medium duty

- Choose textured fingertips for grip on wet tools

Tip: Use lighter gloves where you change often. Use stronger gloves only where needed.

Get the size mix right

The wrong size wastes money and time. Stock a full range and track picks.

- XS–XL to fit all hands

- Color-code sizes on shelves

- Place the most-used sizes at eye level

- Review size pulls weekly and adjust orders

A good fit lowers tears and boosts speed.

Control cost per pair with smart buying

You can lower total costs without risk. Use these steps:

- Buy by the case for volume price breaks

- Lock a delivery schedule to avoid rush fees

- Split SKUs by station so you do not over-buy one type

- Use first in, first out to avoid old stock

Ask for pack data:

- Pairs per box, boxes per case

- Weight per case for freight math

- Shelf life and storage tips

Forecast use with simple math

Use your station map and shifts to plan your order.

- List pairs per task per hour

- Multiply by hours per shift

- Multiply by number of stations

- Add a 10–15% buffer for peaks

Update the plan each month. Cut or add as seasons change.

Set change rules that save money and protect food

Make clear rules and train to them:

- Change gloves when moving from raw to ready

- Change if torn, sticky, or wet inside

- Change after trash or cleaning

- Wash hands when you switch to a new pair

Post a short chart by each sink. Keep bins close for fast toss.

Build a clean, safe PPE set

Gloves work best with a full food-safe setup.

- Stop splash and stains with a Delantal de plástico PE desechable

- Keep hair away from food with disposable hair nets for food service and cooking

- Speed wipe-downs at stations with a non woven disposable cleaning wipes roll

- Handle spills fast with an rollo de papel absorbente de cocina desechable

These low-cost add-ons protect food and reduce glove use from messy rework.

Train for fast, clean glove changes

Teach a simple method:

- To put on

- Wash and dry hands

- Pick the right size

- Pull by the cuff and smooth fingers

- To take off

- Pinch the cuff

- Peel inside out

- Hold in gloved hand

- Slide a finger under the other cuff

- Peel and wrap inside out

- Toss in the right bin

- Wash hands

Post it with pictures near every sink.

Store gloves right to protect value

Bad storage hurts quality and costs money. Keep it simple:

- Store in a cool, dry area

- Keep away from heat and sun

- Do not crush cases

- Keep boxes clean and closed

- Pull from the front; restock from the back

Good storage keeps film strong and easy to don.

Cut waste with layout and labeling

Small layout changes save big:

- Place glove boxes at each station

- Use shelf tags with station names

- Label boxes with “light duty” or “medium duty”

- Keep a small backup stash at peak lines

- Audit trash bins for half-used pairs

Fix what you find in the audit with quick coaching.

Balance durability and dexterity

Too thick can slow you down; too thin can tear. Match glove feel to the task.

- Dexterity first for garnish and plate work

- Grip first for wet and oily tasks

- Tear hold for heavy pans and trays

Test three options on real tasks. Pick the best mix of speed and hold.

Build a simple vendor plan

A strong plan keeps stock steady and costs lean.

- Two approved options per glove type (primary and backup)

- Standing orders set by month, review by week

- Clear specs for size range, film weight, and texture

- Ship windows that match peak season

Keep a one-page sheet with SKUs, pack counts, and reorder points.

Speed up line turns with roll stations

For rapid stations, consider rolls or easy-pull packs:

- Place rolls at eye level

- Set a small bin for used pairs

- Add a wipe bucket for quick clean

- Use a timer cue for change points in rush hours

Fast setup lowers cross-contact and cuts stress.

Daily checklist for supervisors

Use this quick list on every shift:

- Are the right guantes desechables at each station?

- Are sizes XS–XL in stock and easy to reach?

- Are change rules posted and followed?

- Are bins near every change point?

- Are aprons, hair nets, and wipes in place?

- Is storage cool, dry, and tidy?

- Any tears or fit issues to report?

Common mistakes to avoid

- Chasing the lowest price and ignoring tear rate

- Using one glove for all tasks

- Poor size range, causing tight or loose fit

- Far glove stations, making staff skip changes

- Over-ordering one type and running out of another

- Skipping hand wash when switching to a new pair

Fix these and watch costs drop.

Simple KPIs to track

Track a few numbers to prove value:

- Pairs used per 100 meals

- Pairs used per station per shift

- Tear rate per box

- Late change events per shift

- Stockouts per month

Share wins with the team. Tie tips to real results.

Final thoughts

Economical sourcing of disposable gloves for large-scale cooking operations is a system, not a guess. Map your tasks. Pick materials by need. Get the size mix right. Buy smart by the case. Store well. Train fast changes. Pair gloves with simple PPE like aprons, hair netsy wipes. Track a few KPIs.

Do these steps, and you will lower cost per pair, raise speed, and keep food safe. Your line will run smooth. Your staff will feel confident. Your guests will taste the care in every plate.