Breathable disposable coveralls protect workers and help work move fast. They keep out dust, dirty splashes. They also let airflow in, so people stay cooler. In industrial workplaces, this balance matters. It supports safety, comforty productivity at the same time.

What are breathable disposable coveralls?

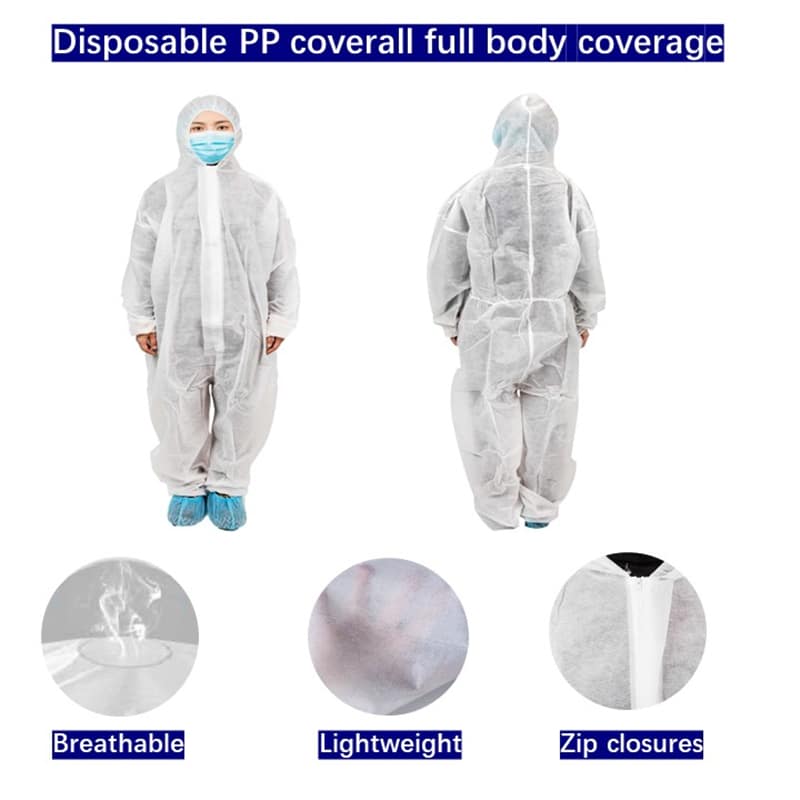

Breathable disposable coveralls are single use full body suits. They cover the torso, armsy legs. Many styles include a hood y elastic cuffs at the wrists y ankles. A front zipper with a storm flap helps block liquids y dust. The fabric allows air to pass while still stopping particles and light splashes.

Common materials include:

- PP no tejido for light and basic use

- SMS for strong and more breathable wear

- Microporoso film for a mix of airflow y barrier

- PP+PE laminated zones for added liquid protection where needed

For a popular option, see these ready picks:

- Breathable all-shift choice: breathable disposable waterproof coveralls

- High barrier with airflow: Mono no tejido microporoso desechable

- Extra safety add-ons: Disposable protective coveralls with hood

- Static risk control: Non woven anti static disposable coveralls

Why breathability matters at work

Hot, closed gear can cause heat stress. It can slow the team. It can raise mistakes. Breathable disposable coveralls lower the heat load by letting air move. This gives three clear wins:

- Comfort. Less sweat, less stick, and better focus.

- Performance. Easier movement and steady pace for long shifts.

- Safety. Lower risk from fogging, fatigue, and quick overheat events.

Barrier protection you can trust

Good coveralls must block what you do not want on skin or clothes. Breathable styles still give strong barrier:

- Stop dry particles como dust, powdery fibers

- Resist light liquid splashes y spray

- Cut cross-contamination when you move from one zone to the next

Para paint spray, powder, cleaning, maintenancey packaging lines, this mix is ideal. When risk is higher, choose microporous or add PP+PE front zones.

Key advantages for industrial workplaces

Here are the main gains when you switch to monos transpirables desechables:

- Cool comfort. Air can pass through the fabric to control sweat.

- Lightweight. Less bulk helps with reach, climb, and precision work.

- Consistent protection. New suit each time means no old soil or hidden tears.

- Low lint. Helps keep parts and tools clean in assembly y pack rooms.

- Fast changeover. Single use suits are easy to don y doff.

- Cost control. No laundry o repair cycle; simple stock and issue.

- Flexible uses. Fit for warehouses, workshops, food areas, and light chemical tasks.

Where to use breathable disposable coveralls

You can use them in many industrial workplaces:

- Manufacturing. Powder blend, assembly, and equipment care

- Spray and paint. Fine mist and light overspray control

- Food processing. Pack lines, prep zones, and clean downs

- Pharma and labs. Low lint cover and easy change

- Construction and maintenance. Dusty jobs, debris, and grime

- Logistics. Cross-dock and returns sorting with mixed soils

If your job has heavy splash or harsh chemicals, choose a higher barrier mix or add aprons, sleevesy cubrebotas as needed.

Materials that balance airflow and safety

Pick the fabric that fits the risk y heat at your site:

- PP non woven. Light duty. Best for dust and dry work.

- SMS. Strong, more breathable, and stable for long shifts.

- Microporous. Film with micro holes for airflow y splash block.

- PP+PE laminated zones. Extra front shield for liquids.

Not sure which to choose? Try a short trial with SMS y microporous to see what your team prefers.

Design features that help on the job

Look for these details to boost comfort y safety:

- Hood. Covers hair and neck edges for better barrier

- Zipper with storm flap. Seals the front opening from spray

- Elastic cuffs y ankles. Close fit to gloves y boots

- Elastic waist or shaped back. Helps range of motion

- Reinforced seams o taped seams in high stress areas

- Anti static options for dust-prone or electronics areas

- Color choices for zone control and quick role tags

Fit and sizing tips

A good suit must fit well to work well:

- Choose the right size. Stock from S to XXL and up

- Check reach. Lift arms and squat; no tight pull at the back

- Sleeve fit. Gloves should overlap cuffs with no gap

- Leg length. Ankles should sit over work boots without drag

- Hood fit. Should sit flat around the face gear and not block view

Donning and doffing basics

Train teams to use coveralls the right way:

- Donning

- Inspect for tears o holes

- Step in and pull up to the waist

- Insert arms, close the zipper, seal the storm flap

- Fit hood if used; set gloves over cuffs

- Doffing

- Peel from the hood and shoulders down

- Roll the outside in to trap soil

- Remove gloves last and dispose in the right bin

Change the suit if it is soiled, torn, or after a zone change.

Cost and hygiene benefits

Breathable disposable coveralls cut hidden costs:

- No laundry, no wait for repairs

- Lower risk from worn reusables

- Clear hygiene steps with single use

- Easy inventory and simple issue at shift start

Use simple FIFO storage to protect shelf life and keep a small buffer stock for peak days.

Safety add-ons to consider

You can pair suits with other PPE to match the job:

- Sleeve covers for wet tasks

- Shoe covers o cubrebotas for floor splash

- Aprons for front-heavy spray

- Gloves, masksy eye protection based on the task

If your line needs more liquid repellent o spray control, test microporous suits first. If static is a risk, add an anti static suit to your list.

Simple checklist for buyers

Use this quick list when you source monos transpirables desechables:

- Task risk y barrier needs are clear

- Material matched to heat and splash risk

- Right design: hood, storm flap, elastic cuffsy ankles

- Sizes for all staff and steady stock on core sizes

- Low lint for clean work areas

- Easy donning y doffing steps in each pack

- Clean labels with lot number y expiry

- Fair cost with no drop in protección

Bottom line

Breathable disposable coveralls give workers the protección they need and the comfort they want. In industrial workplaces, they help cut heat stress, improve focus, and keep contamination low. Pick the right material, the right features, and the right fit. Train on clean donning y doffing. Keep a simple stock plan. With these steps, your team can work safer, cooler, and faster—shift after shift.