Who Needs Isolation Gowns?

Introduction Isolation gowns, often made from fluid-resistant materials, are a crucial component of personal protective equipment (PPE) in the healthcare industry. Their primary purpose is

It is not easy to introduce all complete information of disposable gowns, here we have classified the information that you may interested on this page. Please click the below content, and find the information which you are most interested. You also could detailed reading all the information from top to bottom on this page, which might take you about 10-20 minutes.

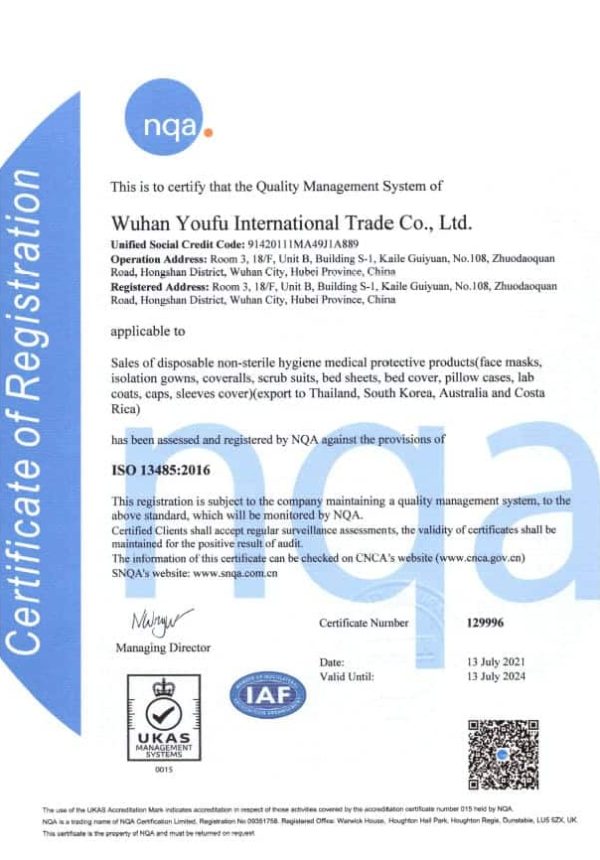

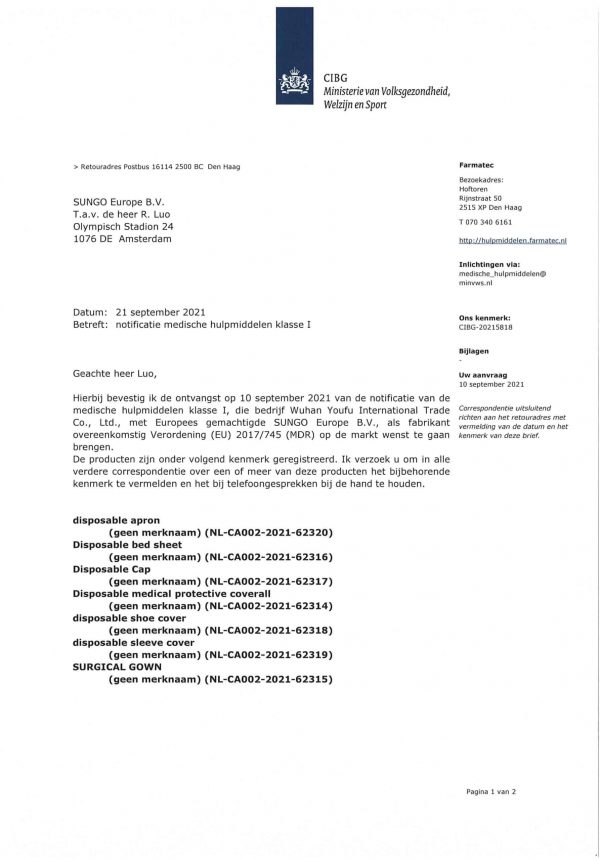

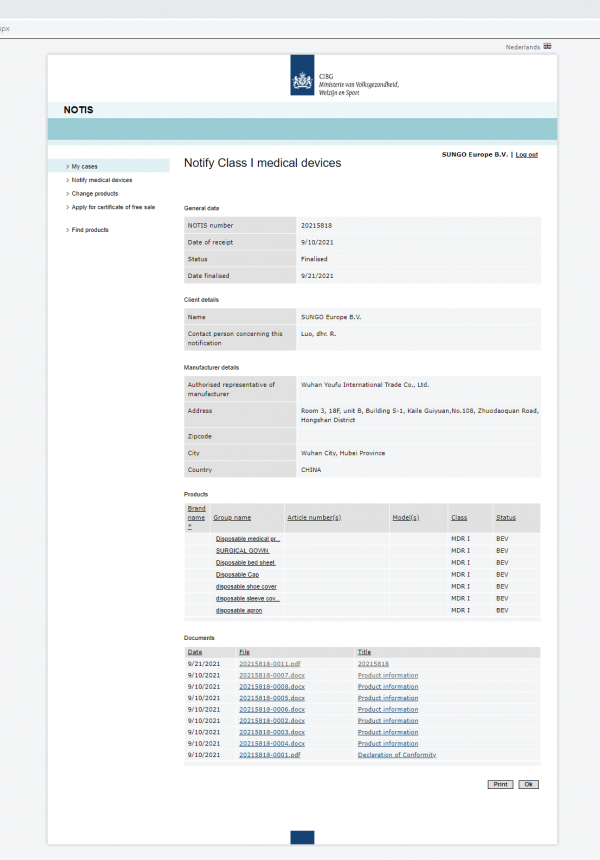

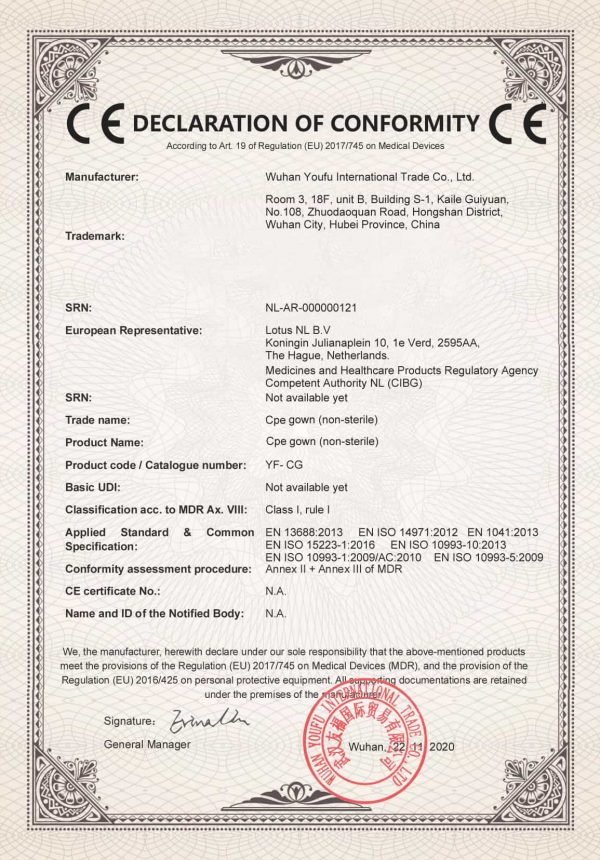

Wuhan Youfu are the leading manufacturer of protective gowns in China. We produce all types disposable gowns, with FDA & CE certification as well ISO13485 Systems Certificate for our quality control system which ensures high safety standards on every product we supply!

These high-quality PP disposable gowns will keep you safe and protected for isolation. Made of durable, fluid-repellent nonwoven material, these gowns are perfect for anyone looking for maximum coverage and protection.

With knitted cuffs and full length coverage, you can rest assured that you’re well-protected against any potential spills or accidents.

Protect yourself from any fluids you might come in contact with during your work shift for a safer experience. Made of high-quality pp+pe material, pe coated all the gown, which makes it 100% waterproof. The most important part is that these garments are Latex Free!

This protective isolation gown can pass AAMI level 1/2/3 test based on different material weight(thickness) and is comfortable enough to wear.

The CPE isolation gowns are useful for healthcare professional, like Doctors and nurses. They are made of durable CPE material to give protection against bodily substances such as blood, saliva, and other fluids. It also has a thumb loop design that makes it easy to wear gloves while wearing the enclosure – this will help prevent infection when dealing with quarantined patients.

Disposable standard surgical gown is made from lightweight, multi-ply SMS material, comfy to wear. These disposable surgical gowns protect the body from outside splashes like blood or other liquid elements with its ultrasonic welding on all the seams. The knitted cuffs and adjustable ties around waist keep it tight for a perfect fit.

Surgical Gown Reinforced is a cloth for surgeons wear during hospital surgery or treatment of patients. It usually made by high quality non woven SMS fabric. The ultra fabric used in the reinforced impermeable sleeves and chest area in the reinforced surgical gown.

Disposable gown is an important item of personal protective equipment (PPE), which is designed to avoid exposure to dust, water, blood, body fluids, and other infectious materials, or to protect people from infection. It is one-piece design and has loose fitting for ease of movement. Mostly with ties on waist and with ties(or velcro) on collar, the disposable gown could cover from shoulder to below the knees against contamination.

The disposable gowns can be divided into disposable isolation gowns, disposable protective gowns and disposable surgical gowns. Based on different levels of protection.

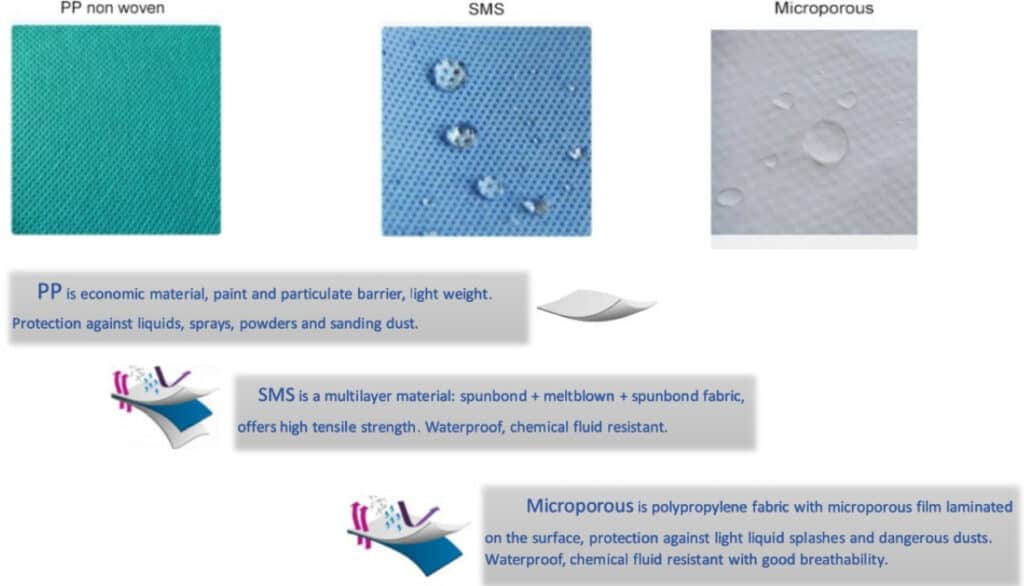

polypropylene non woven fabric is the most common for disposable gown, the weight can be 20-120g/cm², it’s soft, breathable, and cost effective.

It’s tri laminate non woven fabric, it’s made up of a top layer of spunbond polypropylene, a middle layer of meltblown polypropylene and a bottom layer of spunbond polypropylene. The weight can be 25-65g/cm². It’s softer and more durable than PP non woven.

Chlorinated Polyethylene, also referred to as CPE, is considered a thermoplastic material. CPE insulation provides excellent flame and chemical resistance.

PP can coated with PE film. Which is 100% waterproof, but not breathable. The non woven side will be soft and comfortable, while PE film will prevent liquid permeation.

SMS can coated with PE film. Which is 100% waterproof, but not breathable. The SMS side will be soft and comfortable, while PE film will prevent liquid permeation.

Disposable isolation gowns: Used by medical personnel to avoid exposure to blood, body fluids, and other infectious materials, or to protect patients from infection.

Disposable protective gown: Used by clinical staff when exposed to Class A or infectious disease patients managed by Class A infectious diseases. Protective clothing is to prevent medical personnel from being infected and is a single isolation.

Disposable surgical gown: The surgical gown plays a two-way protective role during the operation. First, the surgical gown establishes a barrier between the patient and the medical staff to reduce the probability of medical personnel contacting the patient’s blood or other body fluids during the surgical procedure. Second, the surgical gown can block the colonization/adhesion of the medical staff’s skin or clothing. Therefore, the barrier function of surgical gowns is considered to be the key to reducing the risk of infection during surgery.

Gowns are identified as the second-most-used piece of PPE, following gloves, in the healthcare setting.

Isolation gowns are defined by Association for the Advancement of Medical Instrumentation (AAMI) as the protective apparel used to protect HCWs and patients from the transfer of microorganisms and body fluids in patient isolation situations .

The Food and Drug Administration (FDA) also defines isolation gowns similarly: “a gown intended to protect healthcare patients and personnel from the transfer of microorganisms, body fluids, and particulate material”.

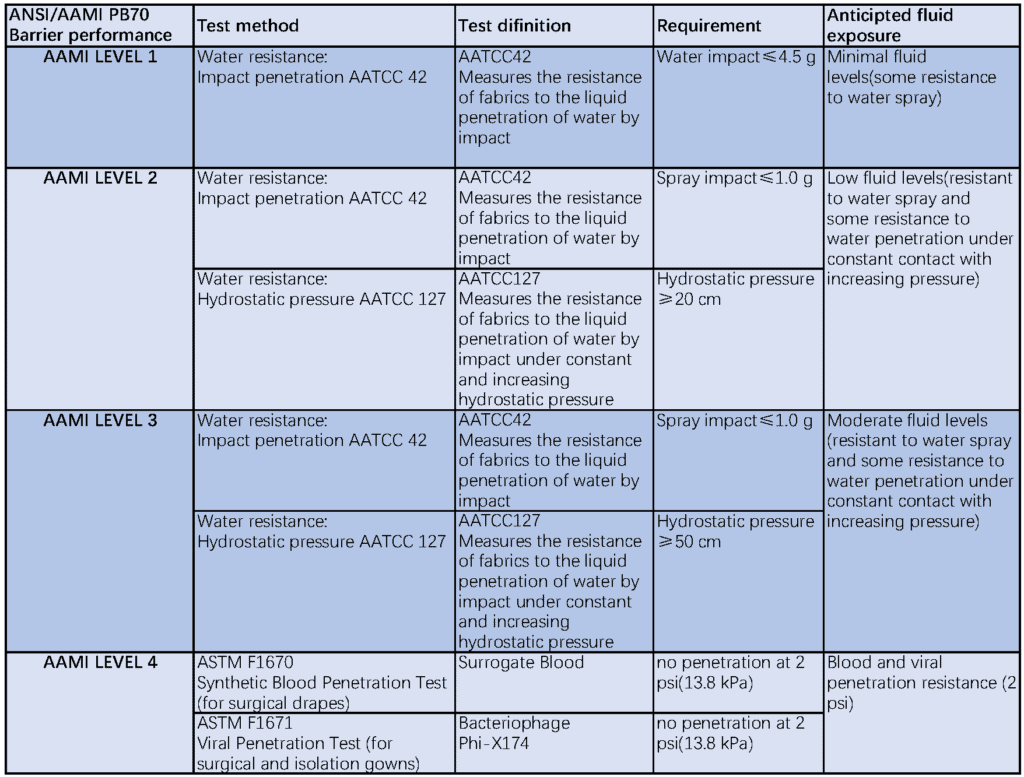

The ANSI/AAMI PB70 standard has 4 levels of fluid barrier protection, with Level 1 being the lowest level of protection and Level 4 being the highest.And there’re 2 Types defined by EN 13795 for EU market.

ANSI/AAMI PB70

These standards are established by AAMI (The Association for the Advancement of Medical

Instrumentation). ANSI (American National Standards Institute)/AAMI PB70:2012

is the standard that establishes a classification system for protective apparel used in health care facilities, including surgical gowns, based on liquid barrier performance using standardized test methods.

The ANSI/AAMI PB70 standard includes 4 standard tests to evaluate standards for liquid barrier performance, with ratings for different levels of gown protection.

Based on the results of these standardized tests, we can see a table below of summarizes the requirements of ANSI/AAMI PB70:2012.

Barrier performance | Test method | Test difinition | Requirement | Anticipted fluid exposure |

AAMI LEVEL 1 | Water resistance: Impact penetration AATCC 42 | AATCC42 Measures the resistance of fabrics to the liquid penetration of water by impact | Water impact≤4.5 g | Minimal fluid levels(some resistance to water spray) |

AAMI LEVEL 2 | Water resistance: Impact penetration AATCC 42 | AATCC42 Measures the resistance of fabrics to the liquid penetration of water by impact | Spray impact≤1.0 g | Low fluid levels(resistant to water spray and some resistance to water penetration under constant contact with increasing pressure) |

Water resistance: Hydrostatic pressure AATCC 127 | AATCC127 Measures the resistance of fabrics to the liquid penetration of water by impact under constant and increasing hydrostatic pressure | Hydrostatic pressure ≥20 cm | ||

AAMI LEVEL 3 | Water resistance: Impact penetration AATCC 42 | AATCC42 Measures the resistance of fabrics to the liquid penetration of water by impact | Spray impact≤1.0 g | Moderate fluid levels (resistant to water spray and some resistance to water penetration under constant contact with increasing pressure) |

Water resistance: Hydrostatic pressure AATCC 127 | AATCC127 Measures the resistance of fabrics to the liquid penetration of water by impact under constant and increasing hydrostatic pressure | Hydrostatic pressure ≥50 cm | ||

AAMI LEVEL 4 | ASTM F1670 Synthetic Blood Penetration Test (for surgical drapes) | Surrogate Blood | no penetration at 2 psi(13.8 kPa) | Blood and viral penetration resistance (2 psi) |

ASTM F1671 Viral Penetration Test (for surgical and isolation gowns) | Bacteriophage Phi-X174 | no penetration at 2 psi(13.8 kPa) |

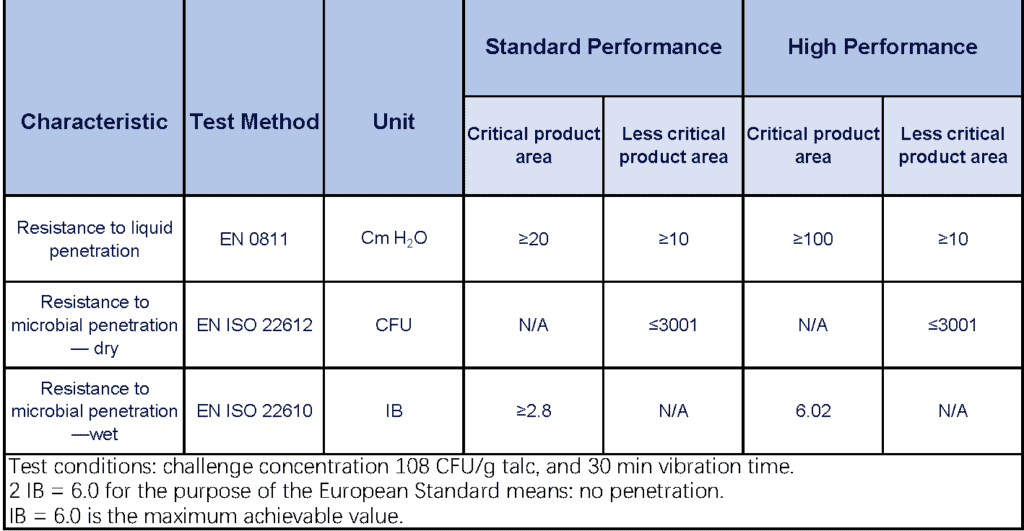

EN 13795 specific performance requirements for gowns. In addition to these tests, EN 13795 requires other characteristics be tested, including microbial and particulate matter cleanliness, linting, bursting strength (dry and wet), and tensile strength (dry and wet). However, performance requirements for these characteristics are the same for both standard-performance and high-performance gowns, and critical and less-critical areas.

We can see a table below of summarizes the requirements of EN 13795.

High Performance | ||||||

Characteristic | Test Method | Unit | Critical product area | Less critical product area | Critical product area | Less critical product area |

Resistance to liquid penetration | EN 0811 | Cm H2O | ≥20 | ≥10 | ≥100 | ≥10 |

Resistance to microbial penetration — dry | EN ISO 22612 | CFU | N/A | ≤3001 | N/A | ≤3001 |

Resistance to microbial penetration —wet | EN ISO 22610 | IB | ≥2.8 | N/A | 6.02 | N/A |

Test conditions: challenge concentration 108 CFU/g talc, and 30 min vibration time. | ||||||

2 IB = 6.0 for the purpose of the European Standard means: no penetration. | ||||||

IB = 6.0 is the maximum achievable value. | ||||||

Overall, the main difference between the gowns is their resistance to water and other fluids that may arise. The standard was developed to assist healthcare professional workers in making informed decisions when selecting the appropriate product for the anticipated tasks by specifying a consistent basis for testing and providing a common understanding of barrier properties.

Make sure you request the technical data information from your manufacturer!

We have a number of posts about disposable gowns, and we will keep updating these posts in order to give you a better understanding of disposable gowns. If you have any questions, feel free to leave us a comment or contact us directly, we are always ready to answer you!

Introduction Isolation gowns, often made from fluid-resistant materials, are a crucial component of personal protective equipment (PPE) in the healthcare industry. Their primary purpose is

Introduction One ubiquitous symbol of the hospital experience is the patient gown. These garments, often made from light, breathable fabric and sometimes even disposable materials,

Introduction An essential piece of protective gear across various industries is the disposable apron with sleeves. Made predominantly from Chlorinated Polyethylene (CPE), these aprons offer

Wearing a cpe gown is a good way to protect themselves from healthcare workers. SO choosing reputable suppliers for CPE gowns is crucial for ensuring

An isolation gown or disposable medical gowns is a protective apparel worn by healthcare professionals, medical workers, and other personnel when caring for patients. It

Diposable gowns provide an array of advantages for businesses across multiple industries, ensuring a safe and sustainable workspace. Providing cost-savings without compromising safety standards, these

Disposable gowns are designed to protect the wearer from exposure to blood, bodily fluids, and other potentially infectious materials. not all PPE gowns are created equal.

Looking for a guide on purchasing disposable isolation gowns from professional manufacturers? You’ve come to the right place! In this blog post, we will discuss

Are you looking for a way to protect yourself from germs and infectious diseases? Then CPE gowns are an ideal choice. This blog post will

Surgical gowns and isolation gowns are both personal protective equipment, They act as a liquid barrier protection against blood, bodily fluids, and other infectious materials, but

Due to the continuous outbreaks of COVID-19; the labor cost keep rising nowadays,and raw material cost also rise crazily because of the complicated international situation, we are under great pressure on the stability of supply chain in 2022. However,we will always do our best to meet the needs of our customers.

Here are some common risks and issues you might encounter while purchasing.

With more than 10 years’ production and export experience in the PPE field, we are always providing stable and competitive price, consistent quality, on time delivery, 24/7 timely response and professional service. And we will make efforts to minimize your purchasing and shipping costs and provide options for your choice if need.

Meanwhile, we are familiar with all kinds of gowns standard, and we are on the white list of the Chinese government certificated disposable gowns manufacturers. Also with CE/ISO13485/FDA approved.

And we have stable forwarder agents which can provide different price and shipping options based on your requirements,and solve problems which may happen in customs.

The final cost depends on detail specifications and quality you request for disposable gowns, and OEM packing, order QTY, shipment cost and so on.And the price would be totally different based on different specification……. The below is an example for the total cost of ordering 1x40HQ disposable PP isolation gown when arriving to your port:

With packing of 10pcs/bag, 50pcs/carton, 1x40HQ can load 136,000pcs disposable PP isolation gown.

The nearest port to our factory is Wuhan port, also can deliver to Shanghai, Shenzhen, Ningbo ports if needed

$29920

Shipping by sea cost is different for each port, and it changes every 2 weeks, we can only confirm the actual cost before loading.

We have got stable agents, will offer more options based on your requirements.

$800 to $20000

Usually we won’t charge mould fee for 40HQ, only if there are many different and complicated designs.

$200

With packing of 10pcs/bag, 50pcs/carton, 1x40HQ can load 136,000pcs disposable PP isolation gown. The nearest port to our factory is Wuhan port, also can deliver to Shanghai, Shenzhen, Ningbo ports if needed.

Shipping by sea cost is different for each port, and it changes every 2weeks, we can only confirm the actual cost before loading. We have got stable agents, will offer more options based on your requirements.

Usually we won’t charge mould fee for 40HQ, only if there are many different and complicated designs.

For example, one customer requested to load more QTY of gowns in 1x40HQ than normal so that make the shipment cost more competitive, as well as the total cost.

Wuhan YouFu is a specialized manufacturer and exporter of disposable nonwoven and plastic products in China. We have been in this field since 2013, our factories area is over 6000 square meters, with 100,000 class clean rooms and around 300 workers.

After receiving your inquiry, we will give a timely reply and make sure to provide you with an accurate quotation within 24 hours. Prices are generally valid for 1~3 months based on the situation then. We will adjust the price according to the specific needs of the customer until we could reach an agreement.

Once all products details are confirmed, samples can be arranged. We will make samples according to customer needs, like the material,weight, style, size and quantity. Samples can more intuitively allow customers to check the quality and details of products. It is very important to confirm the pre-production samples before confirming the order.

After confirming the product details, we will make a complete proforma invoice according to the product specifications, price and quantity. Customers can arrange payment according to the specific amount and bank account in the proforma invoice provided by our company. Under normal circumstances, our domestic bank account can confirm receipt of the payment arranged by the customer within 1 to 3 days.

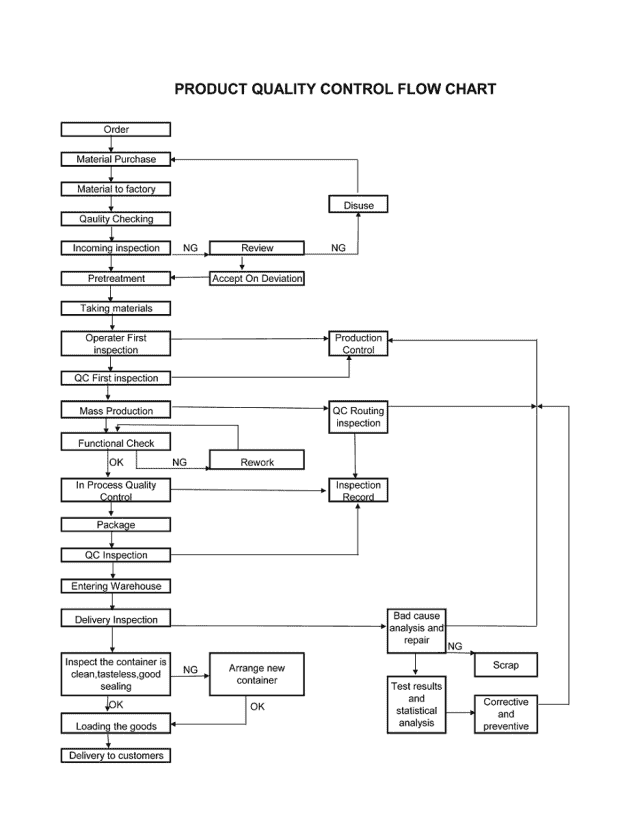

Our bulk production time is generally 20 to 35 days for disposable gowns order. Custom raw material normally takes 5 to 10 days. If it is special material or special color material, it sometimes takes 15 days. After the material arrives at the factory, our quality inspection department will inspect the raw material first, and then start mass production after passing the test. We can also make pre-production samples for confirmation according to customer requirements. During mass production, our quality inspection department will also conduct several random inspections. The bulk production time is around 1-2 weeks. After the mass production is completed, the quality inspection department will conduct the last inspection before the goods leaving the factory, and the shipment can be arranged after the inspection is passed.

Shipping time depends on the destination port’s location and international shipping conditions at that time. Under normal circumstances, it takes about a week for a vessel to arrive at a port in Southeast Asia after leaving the port, about 15 days to arrive in Australia, about 20 days to arrive in South America, about 20 to 25 days to arrive in North America, and 30 to 35 days to arrive in America. The specific shipping time will vary according to international shipping conditions and port congestion.

To ensure the high quality of our products, we have established strict procedures in each stage of manufacturing process to check for any abnormalities and defects. We also eliminate defective product reliably during inspection sessions so that you can enjoy a flawless experience with us!

Our company can formulate personalized solutions according to the specific needs of customers and the particularity of products. Tell us your company’s needs, and we can provide you with suitable solutions based on our more than ten years of production experience and timely shipping information.

Wuhan YouFu is a specialized manufacturer and exporter of disposable nonwoven and plastic products in China.Disposable face mask products are our advantageous products, we have several automatic production lines, which can be produced 7*24 hours.

We offer not only products, but also sales service. The satisfaction of our customers is the main task and mission of the company and in particular of the sales department.

Regarding disposable gowns, your concerns may not end here. If you have more questions, you can always contact us to answer.

We provide OEM / Private labeling on request. Our production facility and support systems are well equipped to undertake private labeling projects.

We manufacture products as per our clients’ desired specifications for private labeling service wherein clients market the products with their brand name.

We have a highly flexible production system that enables us to offer products with low minimum order quantity restrictions. However, the per-unit pricing for lower quantities would be higher than the per-unit price for large amounts.

Regarding to the disposable gowns, Normally the MOQ is 10,000pcs, can be negotiable.

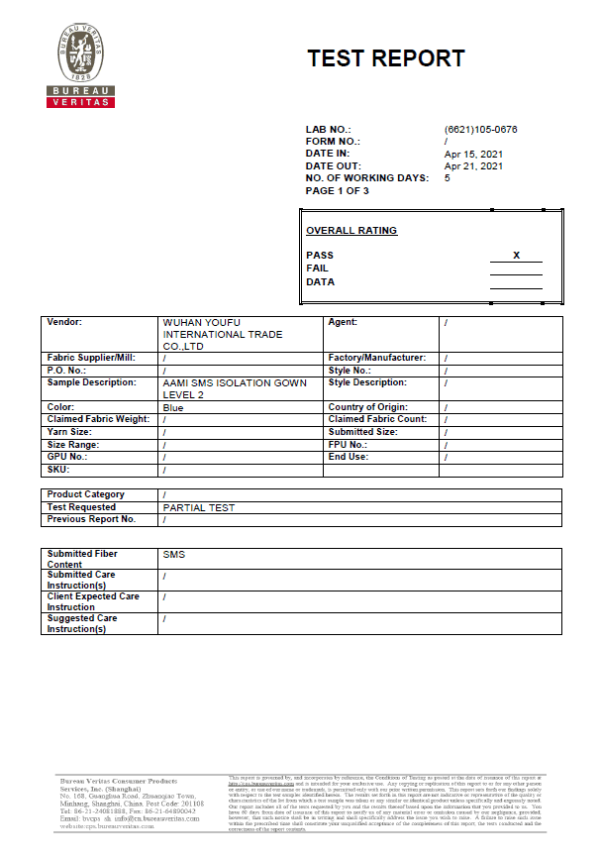

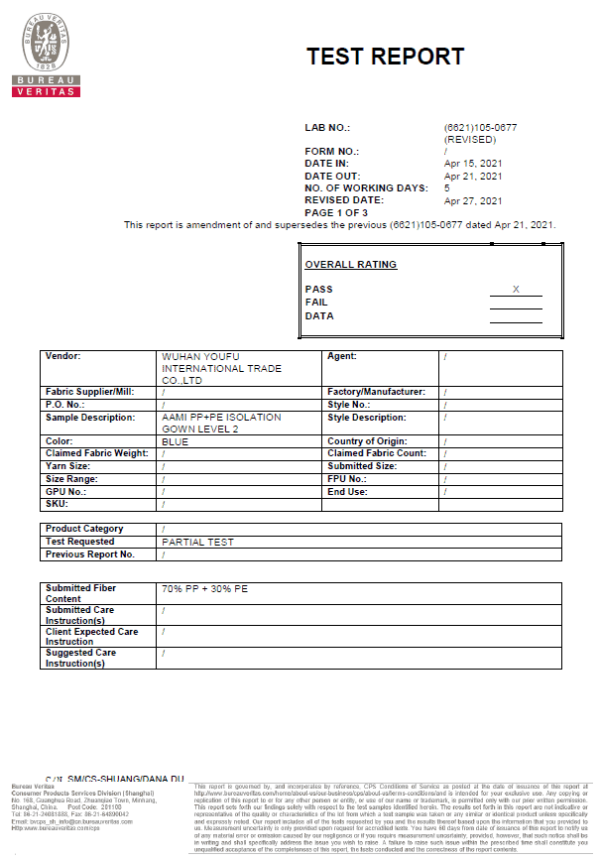

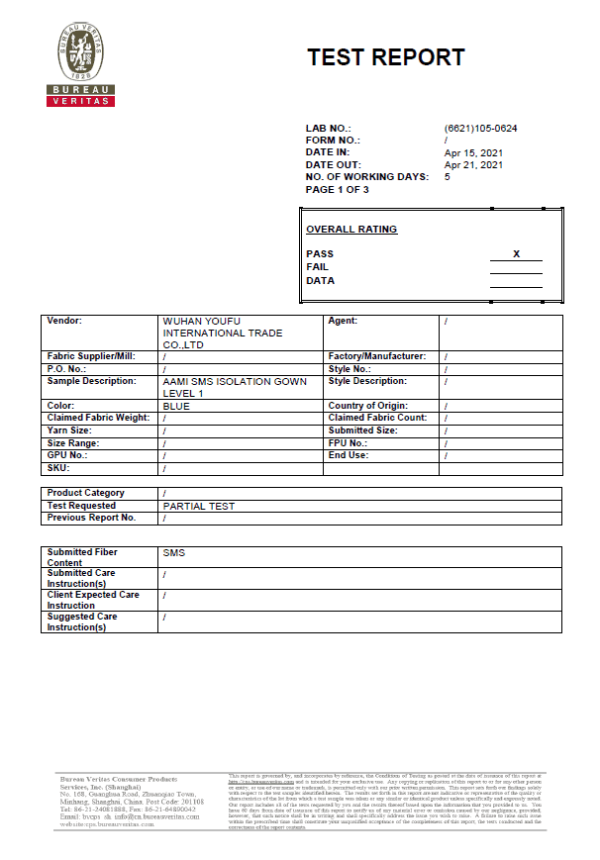

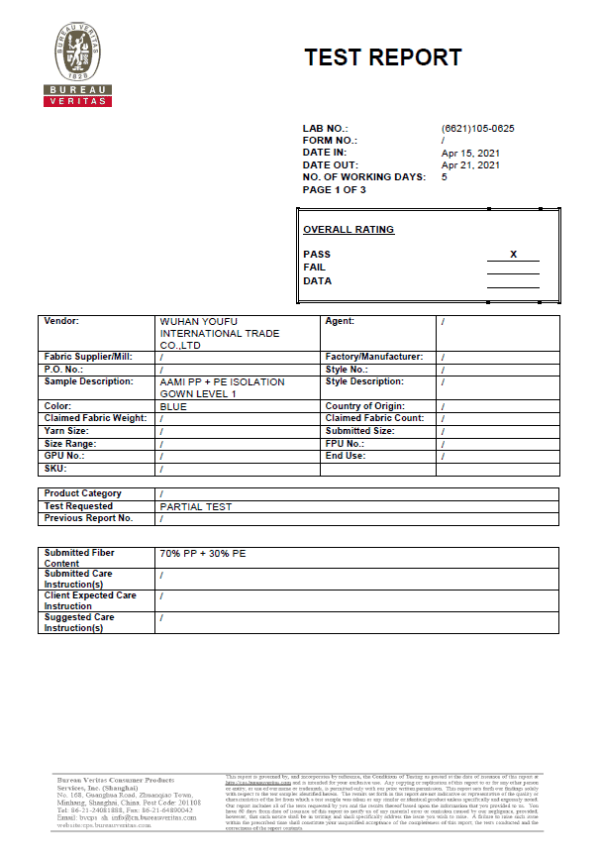

Yes, we’ve got test reports for Level 1,2,3 isolation gowns. And we’ve also got CE and FDA certificates.

We could provide bag packing and individual packing for the disposable gowns. Some customers would request sterile packing with paper-plastic bag, and this is also available.

Yes, we could do customized color for the disposable gowns. You could provide us the Pantone color number, then we could make it in your ideal color.

Yes, normally we could make logo stickers to paste on the disposable gowns. Also we could do customized logo printing on the disposable gowns if you need, just will have some extra printing charge.

We are fully qualified to produce and export disposable gowns, and have complete test reports.

We will contact you within 1 working day, please pay attention to the email with the suffix “@med-disposable.com”.

Note: Your email information will be kept strictly confidential.