Finding the right disposable gowns for hospitals is a big task. You need reliable supply, true quality, and fair price. You also need safe materials, good fit, fast delivery, and clear labels. This guide shows how to start sourcing reliable disposable gowns for hospitals with simple steps you can use today.

Know the gown types

Before you buy, match the gown to the task.

- Isolation gowns. Good for daily patient care, triage, and cleaning. Pick fluid resistant or impervious fronts when splash risk is higher.

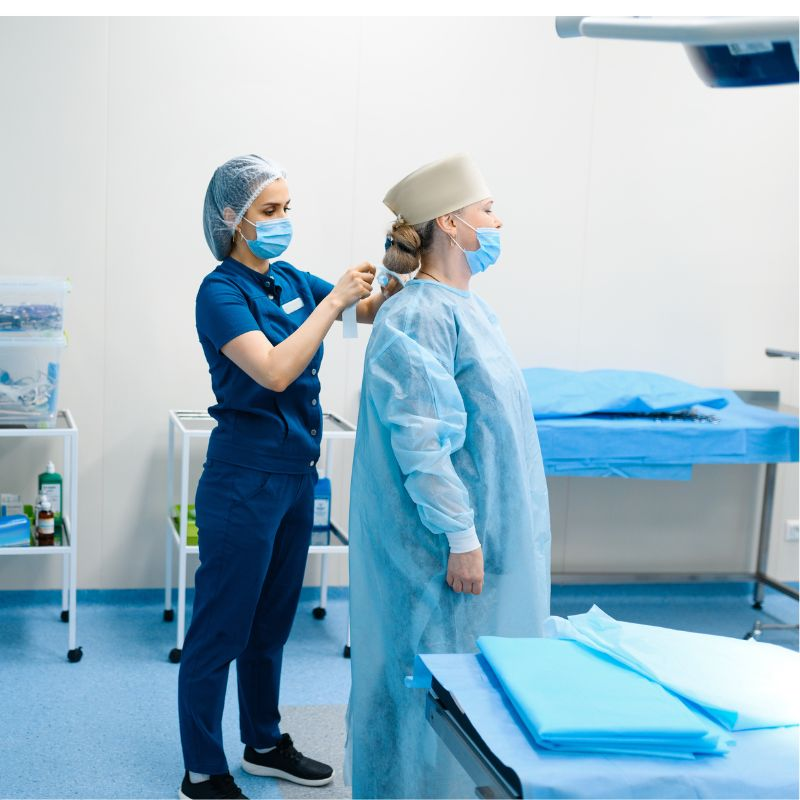

- Surgical gowns. Used in the operating room. They need strong barrier in the critical zones and a good fit for long time wear.

- Patient gowns. Light non woven styles for comfort and privacy.

Helpful options to review:

- Strong, breathable theater wear: Disposable SMS surgical gown https://med-disposable.com/product/disposable-sms-surgical-gown/

- Higher barrier for complex cases: Disposable reinforced SMS surgical gown https://med-disposable.com/product/disposable-reinforced-sms-surgical-gown/

- Simple waterproof coverage for many wards: Blue plastic isolation gowns, fluid resistant PE gowns https://med-disposable.com/product/blue-plastic-isolation-gowns-fluid-resistant-pe-gowns/

- Film-laminated shield for splashes: Disposable PP+PE isolation gown CE certified https://med-disposable.com/product/disposable-pp-pe-isolation-gown-ce-certified/

Check core performance needs

Pick gowns that match your real work. Focus on these points:

- Fluid resistance. Choose the barrier level you need for spray and splash. Front and sleeves should block fluids where it matters.

- Breathability. Staff need to move and work in heat. SMS or microporous can help airflow and cut heat stress.

- Low lint. Low lint helps protect tools and fields from dust.

- Seams. Ultrasonic or taped seams can boost barrier in high splash zones.

- Cuffs and closures. Knit cuffs or elastic cuffs keep wrists sealed. A secure neck and waist ties keep the gown in place.

- Donning and doffing. The gown should be easy to put on and take off with clear steps to avoid contamination.

Pick the right materials

Each material has strengths. Match the cloth to the job.

- PP non woven. Light, low cost, and low lint. Good for basic isolation gowns.

- SMS/SMMS. Strong, more breathable, and stable for longer tasks.

- PP+PE laminated. Film on the front adds impervious protection where you need it.

- Microporous. A breathable film that still blocks splashes.

- PE/CPE film. Simple waterproof film for short, wet work.

Choose sterile or non-sterile

- Sterile. Sealed and ready for clean areas and procedures. Often individually packed for the OR.

- Non-sterile. Ideal for wards, ER, lab, and support work.

For sterile theater needs, see:

- Sterile surgeon gowns, disposable surgical isolation gown https://med-disposable.com/product/sterile-surgeon-gowns-disposable-surgical-isolation-gown/

Get sizes and fit right

A safe gown must also fit well.

- Sizes. Stock from S to XXL so all staff can work and reach.

- Sleeves. Check the sleeve length and cuffs. Thumb loops help keep sleeves inside gloves.

- Coverage. Make sure the front, sides, and back closure match your risk level.

- Mobility. Look for raglan sleeves or roomy cuts for easy reach and lift.

Build a clear specification

Write a short, clear spec sheet so all vendors know the same needs.

- Type. Isolation gown, surgical gown, or patient gown.

- Material. PP, SMS, PP+PE, microporous, or PE film.

- Barrier. State the fluid resistant or impervious zones.

- Design. Knit cuffs or elastic cuffs, thumb loops or no loops, neck closure type, waist ties, and back closure style.

- Packaging. Individually packed or bulk, inner bag, carton count, and label needs.

- Labeling. Ask for lot number, batch, date, and expiry on each unit box or bag.

Vet the supplier

A strong supplier protects your hospital from risk. Use this quick list:

- Capacity. Can they meet your forecast, MOQ, and peak orders?

- Lead time. Ask for normal and rush lead times. Check shipping plans and logistics routes.

- Quality control. What tests do they run on materials, seams, and barrier? Can they share inspection records?

- Traceability. Do they keep lot numbers and batch logs for each carton?

- Samples. Get samples to test fit, barrier, and comfort on site.

- Communication. You need fast, clear replies for changes and urgent needs.

- Backup. Do they have a backup line or partner if demand spikes?

Test before you buy big

Small tests can save you from big mistakes.

- Run a quick water or spray test on the front and sleeves.

- Check seams, cuffs, ties, and back closure after motion and reach.

- Do a 2–4 hour wear test for breathability and heat build-up.

- Try donning and doffing drills with the real PPE stack: gloves, masks, and face shields.

- Note any lint on tools or fields to confirm low lint claims.

Plan your packaging and labels

Good packaging helps speed and safety.

- Unit pack. For clean areas, use individually packed or small inner bags.

- Carton. Ask for strong cartons with clear barcodes, lot number, and expiry.

- Instructions. Include simple donning and doffing steps in each pack if staff rotate often.

- Storage. Confirm shelf life, and store away from heat and wet.

Manage cost without losing safety

Balance price with performance.

- Use tiered buying: basic PP for low risk, SMS for daily wards, PP+PE or microporous for high splash.

- Mix bulk packs for busy wards and individually packed for clean rooms.

- Place a base order and a buffer stock for surge times.

- Track defect rate and returns; use this data to guide the next buy.

Train for safe use

Even the best gown fails without good training.

- Show how to pick the right gown for the task.

- Practice donning with gloves over cuffs or with thumb loops.

- Practice clean doffing to avoid contamination.

- Tell staff to change a gown that is soiled, torn, or after a zone change.

- Place clear bins for single use waste.

Keep a steady supply

A steady flow is part of being reliable.

- Share a 3–6 month forecast with your vendor.

- Set a clear reorder point for each size.

- Use first in, first out to protect shelf life.

- Review lead times each season and plan shipping early.

Sample sourcing checklist

Use this fast list when you review offers:

- Type and material match the spec

- Front and sleeves give the fluid barrier you need

- Knit cuffs or elastic cuffs are firm and comfy

- Neck and waist ties hold up after motion

- Back closure stays closed while reaching

- Seams are neat, strong, and sealed where needed

- Low lint confirmed by a quick check

- Sizes S–XXL available with steady stock

- Clear labels with lot number, batch, and expiry

- Packaging fits your wards and clean areas

- Samples pass your site tests

- Fair lead time with a real backup plan

Helpful product paths

- Theater work with airflow: Disposable SMS surgical gown https://med-disposable.com/product/disposable-sms-surgical-gown/

- Extra shield in critical zones: Disposable reinforced SMS surgical gown https://med-disposable.com/product/disposable-reinforced-sms-surgical-gown/

- Waterproof daily cover for wards: Blue plastic isolation gowns, fluid resistant PE gowns https://med-disposable.com/product/blue-plastic-isolation-gowns-fluid-resistant-pe-gowns/

- Film-laminated isolation with clear specs: Disposable PP+PE isolation gown CE certified https://med-disposable.com/product/disposable-pp-pe-isolation-gown-ce-certified/

Bottom line

Sourcing reliable disposable gowns for hospitals means matching the gown to the job, testing the barrier, and checking the fit. It means simple specs, solid suppliers, clear labels, and steady logistics. Use smart materials like PP, SMS, PP+PE, microporous, or PE film to balance breathability and fluid resistance. Train teams on clean donning and doffing. Keep buffer stock and plan lead time early. With these steps, your hospital can source disposable gowns that are safe, reliable, and ready when people need them most.