Nonwoven fabrics are often used in medical gowns. They offer some advantages over woven fabrics. Nonwoven fabrics are more absorbent and can be made to be more breathable than woven fabrics. This makes them a better choice for use in medical gowns, where absorbency and breathability are important factors.

What is non-woven technology

Non-woven technology is a manufacturing process that produces fabrics from synthetic fibers, rather than from natural materials like cotton. These fabrics are generally lighter and thinner than traditional fabrics, and can be made in a variety of shapes and sizes. Non-woven fabrics are often used in medical applications, because they are less likely to cause skin irritation than traditional fabrics.

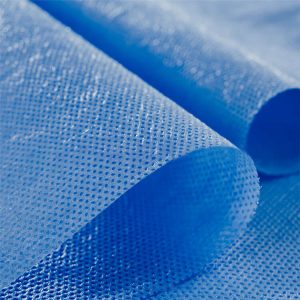

Non-woven fabrics are made by bonding together fibers using heat, pressure, or chemicals. The resulting fabric is strong and durable, and can be used in a variety of applications. Non-woven fabrics are often used in medical applications, because they are less likely to cause skin irritation than traditional fabrics.

SMS

The material of SMS disposable surgical gown is made of polypropylene, which is a composite material formed by spunbond and meltblown process and reinforced by hot pressing. The color of the product is also obtained by adding color masterbatches to the spunbond solution.It can be made in many colors,usually blue ,white and yellow.

SMS material combines the good tensile resistance of spunbond with the excellent filtering and shielding performance of meltblown fabric, and makes up for the shortcomings of poor permeability of spunbond and low strength of meltblown fabric, achieving the purpose of complementing the shortcomings and concentrating the advantageous performance.Of course,this sort of material has some disadvantages.

Development of non-woven technology in recent years

Nonwovens is one of the youngest and most promising emerging fields in the textile industry. China’s nonwoven industry started late, but is developing very rapidly. At the early stage of development, nonwovens were mainly used in the garment industry as auxiliary materials.

With the rapid development of social economy and science and technology, new products and technologies of nonwoven fabrics are emerging and changing day by day, and the scope of application is becoming more and more extensive.

Especially in 2020, due to a new round of epidemic, most industries experienced a period of shutdown and various economic activities were temporarily brought to a halt. In such a situation, the nonwoven industry was instead busier than at any other time.Such a social environment provide a market for it.

With demand for products such as disinfectant wipes and masks reaching unprecedented levels this year, news reports about a surge in demand for base materials (i.e. meltblown materials) becoming mainstream, and many people hearing a new word for the first time – nonwovens – people are beginning to pay more attention to the important role nonwovens play in protecting public health.There is every sign that non-woven techonlogy is developing rapidly.

With the continuous emergence of new technologies, the functions of nonwoven fabrics are constantly improved. The future development of nonwoven fabrics comes from the continuous penetration into other fields such as new industries and automobiles; at the same time, we eliminate backward and old equipment, produce functional, differentiated and diversified world-class nonwoven products, and march to the depth of production, deep processing the products to form product diversification and adapt to the market demand.

In addition, in the two fields of disposable hygiene absorbent materials and wiping products, the trend of consumer upgrading is very obvious. With the development of the economy, people have higher and higher requirements for the functionality, comfort and convenience of hygiene care products, and nonwoven fabrics with specific properties are more and more widely used in related fields. In the future, in disposable absorbent materials and wiping products, the technical upgrading of nonwoven fabrics is still a major trend.Nonwoven material has becoming a big business. Many orders from overseas.

Application of Nonwoven Materials in Medical Field

application of non-woven materials in medical products

Medical products are one of the most important application fields of nonwoven materials at present. At present, it has been widely used in gauze block, hemostatic plug, mask cloth, operating clothes, ward sheets, pillows, wound dressings, drug paste paste, band-aids, medical tape, medical bandages and medical rags and accessories.Nonwoven materials become a universal application.

Operating room supplies

This category of products is the largest category of medical and health applications, including: disposable sugical gown, surgical back stand cover, surgical towel, birth pad, surgical drape and sheets, level 4 surgical gown and other accessories.

Early in the operating room supplies mainly made of woven fabrics and knitted fabrics, then by use of wood pulp composite spunlace nonwoven technology, production is breathable, strength, evenness, composite performance all meet the requirements of the medical pulp composite spunlace nonwoven, then after finishing to alcohol resistance, resistance to blood fluoride through three resistance, the penetration performance of antimicrobial effect.

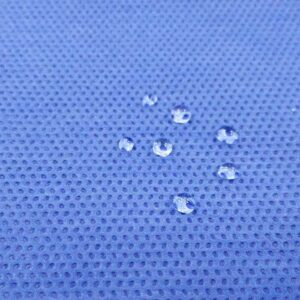

As SMS material has the advantages of high water pressure resistance, good shielding, light weight, high strength, waterproof and oil-proof, low price, etc., people have been widely used in recent years, is gradually replacing the status of traditional woven fabrics.

According to statistics, at present, there are more than 60,000 hospitals and 115,000 medical clinics and nearly 4.5 million beds in China. If all of them are replaced by disposable non-woven fabrics, the annual demand for medical non-woven fabrics will be considerable.

Protective equipment

Protective equipment includes N95 mask, various protective clothing, mainly anti-virus gown, and various anti-radiation gown and other affiliates.

Medical protective equipment has a particularly high shielding requirement for bacteria and viruses, like a barrier protection and requires breathability, moisture permeability and portability. It is an important equipment for protecting doctors and ambulance personnel.In recent years, SARS, avian influenza and influenza a (H1N1) and other public health events have promoted the development of non-woven protective products.At present, flash steaming, melt spraying and SMS composite nonwoven fabric processing products are more commonly used.

Nonwovens in recent years, plays an extremely important role in the medical field, the rapid development of nonwoven fabric, for medical and health materials in great change and improve the product structure and performance level believes that with the innovation and development of nonwovens technology, the application of nonwovens in the medical and health supplies, will get rapid popularization and application of its technology will be further perfected and improved.

What is surgical gown

Surgical gown is a type of clothing that is worn by medical professionals during surgery. It is typically made from nonwoven fabrics to provide protection against blood and other bodily fluids.It is a barrier protection.level 4 surgical gown are common.

The gown may also be sterile to prevent infection.

There are different types of medical surgical gown, depending on the level of protection they offer. Some gowns are made from disposable materials, while others are reusable.

Medical operation gowns can be made from a variety of materials, including polyester, cotton,and other items.

Material of nonwoven

Nonwoven fabrics are made from synthetic or natural fibers that are bonded together using heat, pressure, or a chemical adhesive.

Nonwoven fabrics offer a number of advantages over traditional woven fabrics, including:

- They are stronger and more durable than traditional fabrics.

- They are less likely to tear or rip.

- They are softer and more comfortable to use.

- They are easier to clean and require less maintenance.

Advantages of using nonwoven in surgical gowns

- Nonwoven fabrics are less likely to cause skin irritation or allergic reactions.

- They are more absorbent than traditional fabrics, which makes them ideal for use in medical applications.

- They can be easily sterilized to prevent the spread of infection,like the barrier protection.

- They are durable and can be reused multiple times.

Wuhan YouFu is a specialized manufacturer and exporter of disposable nonwoven and plastic products,with over 10 years of experience. If you’re looking for high-quality, affordable surgical gown, please check out our website or contact us today! Thanks for reading!