Introduction

Sourcing from a disposable apron roll manufacturer can be a daunting task. Several factors must be considered, from the compliance with food contact approved materials and FDA food contact regulations to the understanding of different apron materials and their applications.

Understanding Disposable Aprons

Disposable aprons serve as a crucial barrier to safeguard both users and products, finding extensive use in industries like healthcare and the food sector. The demand for disposable plastic aprons has surged due to their efficiency and convenience.

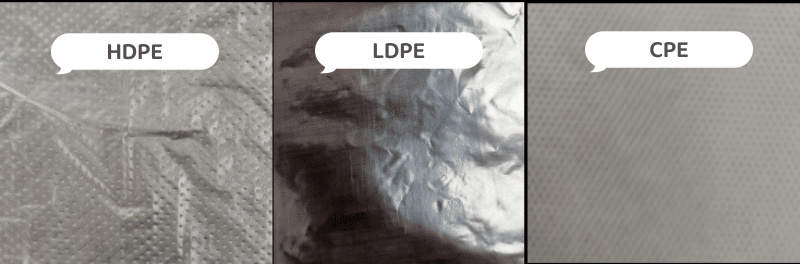

HDPE vs LDPE Aprons: Different Applications and Ranges

There are various types of disposable aprons available, most notably High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) aprons. HDPE aprons are thinner and more resistant to chemicals, ideal for laboratories and environments with chemical exposure. On the other hand, LDPE aprons are thicker, making them perfect for high-temperature applications and areas requiring substantial physical protection.

The Convenience and Intention of Apron Roll Packaging

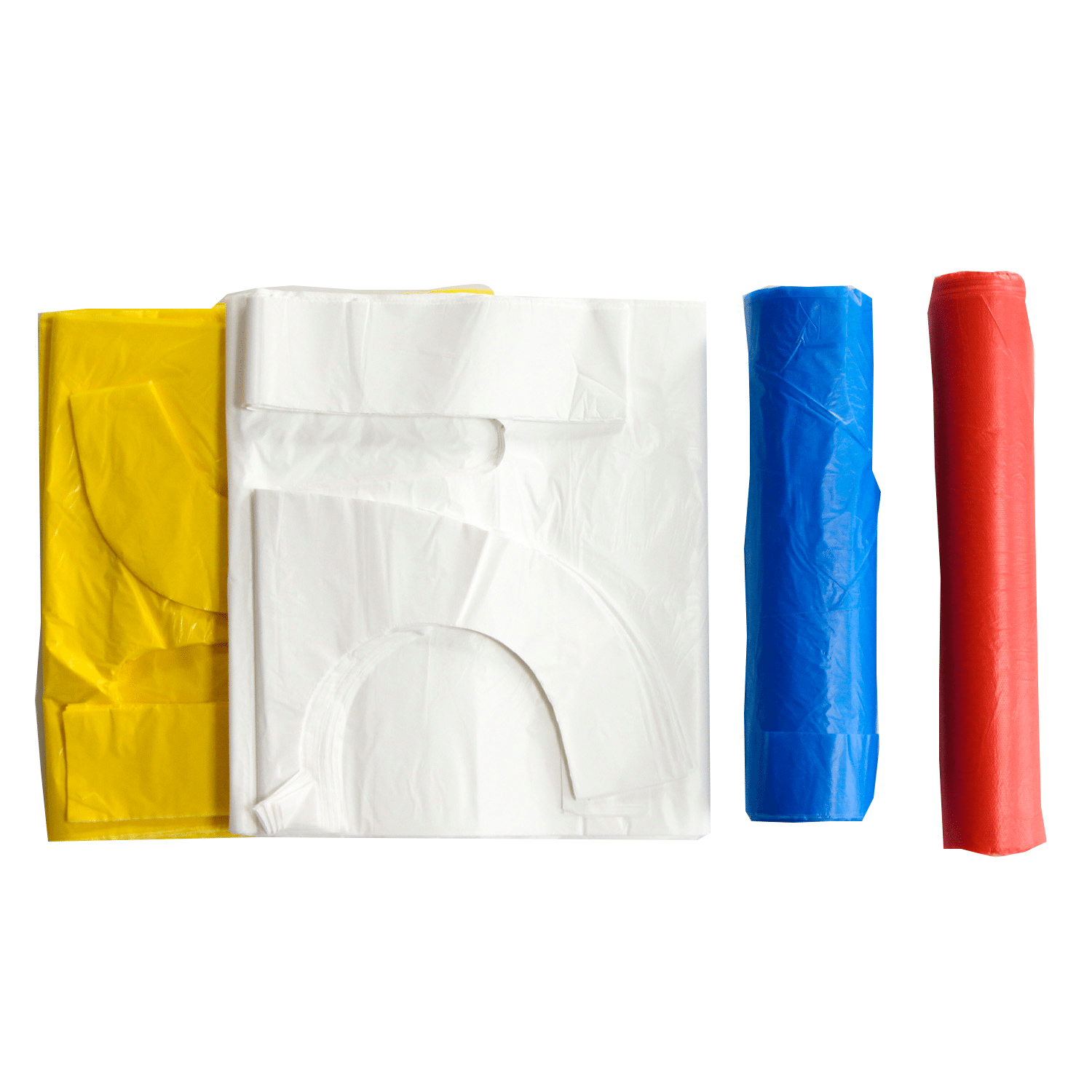

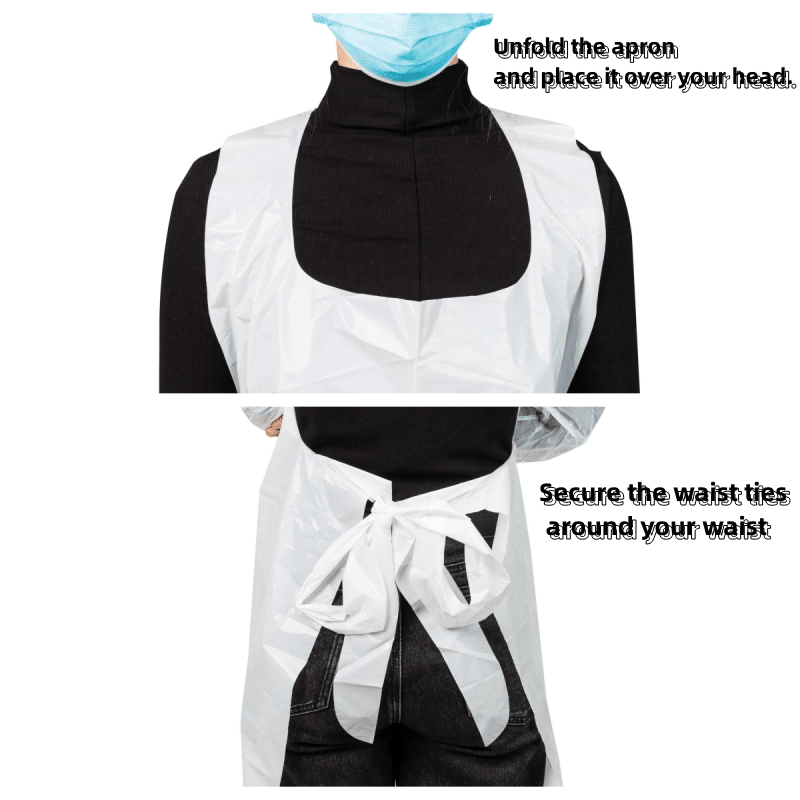

The concept of disposable apron roll packaging brings immense convenience. It enables easy storage and quick access, significantly reducing the preparation time. This packaging style allows easy dispensing of aprons in high-traffic areas, ensuring hygiene standards are maintained without compromising efficiency.

Importance of Food Contact Approved Materials

When purchasing disposable aprons, ensuring they’re made from food contact approved materials is paramount. This requirement guarantees that the aprons are safe for use, especially in food processing environments.

FDA Food Contact Regulations

Compliance with FDA food contact regulations is a must for all manufacturers. This means the materials used in the manufacturing process are safe for contact with food, minimizing risks while boosting users’ confidence.

Selection Criteria for Disposable Plastic Aprons

Selecting disposable plastic aprons involves numerous considerations. Among the most important are quality, safety standards, and the apron’s ability to prevent cross contamination in the processing environment.

Key Considerations in the Food Chain

Disposable aprons are the go-to for most companies within the food chain due to their efficacy in preventing cross contamination.

Preventing Cross Contamination

Cross contamination prevention is crucial in the food industry, and disposable aprons provide a reliable solution. Their use helps minimize risk, creating a safer processing environment.

The Wide Product Range Offered

Leading manufacturers offer a broad spectrum of products that comply with all FDA food contact regulations. They provide not only disposable aprons but also disposable smocks for added protection. Samples are also provided for quality assurance.

Benefits of Using Custom Products

Beyond standard offerings, custom products offer increased flexibility and effectiveness in meeting specific needs. For instance, disposable aprons can be tailored to different sizes and colors. These customizations help ensure the aprons perfectly fit into your business operations and enhance safety.

Conclusion

In conclusion, sourcing from a disposable apron roll manufacturer involves several considerations. From material safety to functionality, and from packaging convenience to understanding the different types of apron materials, every aspect is crucial. Disposable aprons play a vital role in maintaining hygiene standards and preventing cross contamination. Always source from manufacturers that comply with FDA food contact regulations to ensure optimum safety.

FAQs

What is the importance of food contact approved materials in disposable aprons?

Food contact approved materials ensure that the aprons are safe to use in food processing environments.

What are the differences between HDPE and LDPE aprons?

HDPE aprons are thinner and more resistant to chemicals, making them ideal for environments with chemical exposure. LDPE aprons are thicker and suitable for high-temperature applications and areas requiring substantial physical protection.

What is the benefit of apron roll packaging?

Apron roll packaging provides easy storage and quick access, which significantly reduces preparation time. It is particularly useful in high-traffic areas.

How do custom products enhance the use of disposable aprons?

Custom products allow for specific modifications, such as size and color, which can better fit into business operations and enhance safety.

What should be considered when sourcing from a disposable apron roll manufacturer?

Considerations should include compliance with FDA food contact regulations, the availability of custom products, the capacity to prevent cross contamination, and the convenience of the packaging method.