Disposable bouffant caps are light, stretchy head covers. They keep hair contained and stop loose hairs or skin flakes from falling. You see them in hospitals, lab rooms, and food factories. Getting a steady supply is important for your business. But how do you team up with the right manufacturers for the long haul? Let’s break it down.

Why You Need a Steady Supply

Here’s why you should partner for long-term supply:

- No Surprises: Keep the same quality cap every time.

- Save Money: Ordering bulk often costs less per cap.

- Be Ready: Never run out. Always have what you need.

- Trust: Build a bond so the maker knows YOUR needs.

Steps to Find and Work With a Maker

Follow these steps to choose a manufacturers and make a deal:

- Know Your Needs

- How many caps do you need each month?

- What size, color, or material works best?

- Check for quality: The cap shouldn’t rip or slip off.

- Look For a Good Maker

- Find a company that makes disposable bouffant cap items.

- Ask for samples to test comfort and fit.

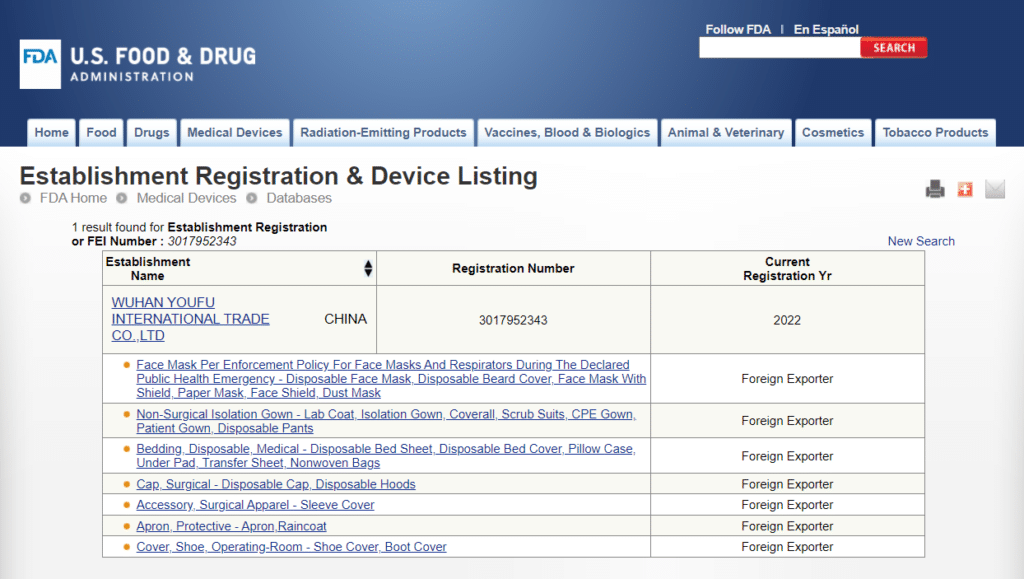

- Do they meet rules for use in your field (like health care)?

- Talk Clear Plans

- How fast can they make and ship your caps?

- What if you need more or less some months?

- What cost breaks do they give for big orders?

- Set Up a Deal

- Sign a paper that says how many caps, when to send, and costs.

- Plan how to solve problems if goods are late or don’t match quality.

- Keep In Touch

- Chat often. Tell them what works or what needs to change.

- Ask how they can make the cap even better!

Why Quality Matters

A flimsy cap won’t block loose hairs or germs. Bad caps may tear or let hair out. Be sure your maker cares about quality:

- They use strong but soft material.

- Every cap should pass a quick stretch and fit test.

- Check packs to make sure caps don’t come dirty or hurt.

The Perks of Long-Term Ties

Working with one maker for supply for the long haul? It gives gains:

- Saves Cash: Less spent per cap.

- Grows with You: They know your needs as you add items.

- Quick Fixes: Less down time as they know your goals.

- Trust Builds: Less worry each time you order.

Related Goods

Want other safe wear like bouffant caps? Check out:

- Safe head covers like Disposable SMS caps for doctors

- Coveralls for full body shield: Breathable disposable waterproof coveralls

- Shoe shields to keep clean: Disposable standard non skid boot covers

Wrap Up

The right partnership with disposable bouffant cap manufacturers keeps your space clean and safe. It saves time and cash. Pick a maker you can trust. Test what they make. Talk clear rules. Then build a strong bond for long-term supply. When both sides win and know each other, you’ll get the best caps for your needs!