Introduction

Ever wondered how disposable nurse gowns are made? These unsung heroes play an indispensable role in medical environments, safeguarding professionals from potential contaminants and ensuring patient safety. In this article, we’ll delve deep into their intricate creation process.

The Importance of Nurse Gowns

Nurse gowns are not just garments; they’re protective barriers. Every medical professional can attest to the importance of these gowns. Beyond mere cleanliness, they act as a frontline shield against potential health threats, ensuring both the wearer and patient remain in a sterile environment.

Raw Materials

Behind every durable and efficient gown lies its fundamental component: raw materials. Selecting the right materials can make a significant difference in protection levels.

Commonly Used Fabrics

While polypropylene remains a favorite for its lightweight yet sturdy nature, various other materials are also chosen based on specific needs. Polyester offers great flexibility, while polyethylene provides an additional layer of moisture resistance. Combined, these fabrics deliver optimal protection.

Environmental Considerations

In today’s world, the environmental footprint of products can’t be ignored. With millions of disposable gowns used daily worldwide, manufacturers are focusing on minimizing waste and promoting recyclability. The balance between patient safety and environmental responsibility is a tightrope manufacturers walk daily.

Key Manufacturing Processes

From a roll of fabric to a finished gown, several meticulous processes are involved.

Cutting and Stitching

Precision is vital. Modern machinery, equipped with state-of-the-art technology, ensures each cut is accurate. Once the pieces are ready, they are stitched together. While machines handle most of the process, human oversight guarantees consistency and quality.

Sterilization

Post assembly, these gowns can’t be sent out just yet. They’re subjected to high-grade sterilization techniques, ranging from autoclaving to ethylene oxide treatment, ensuring every microorganism is eradicated.

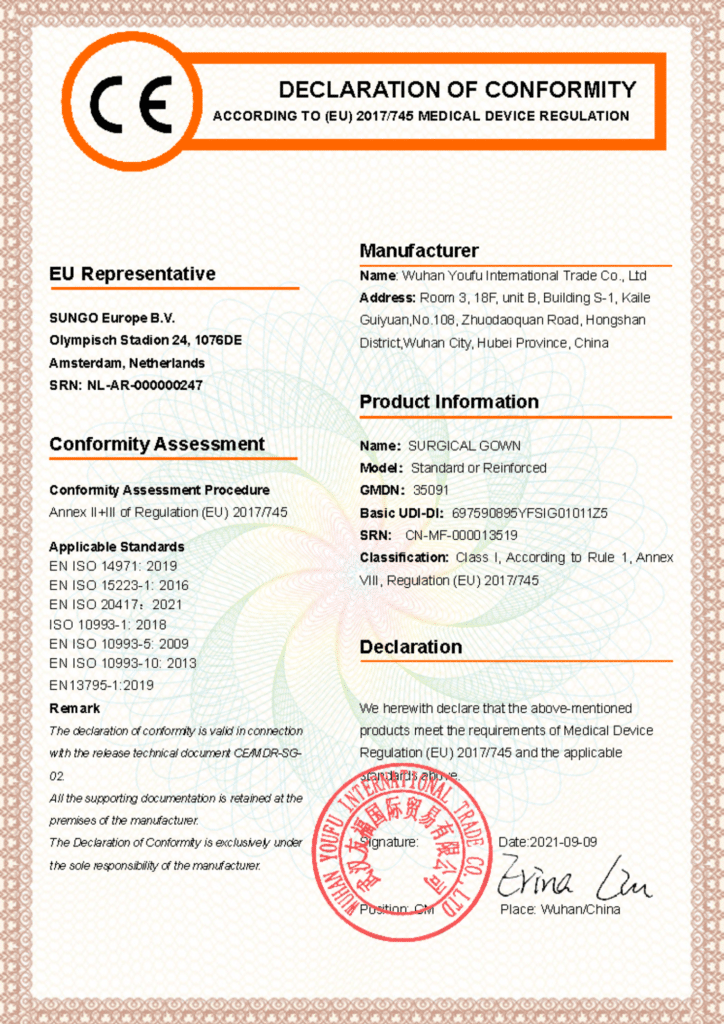

Standards and Regulations

Patient safety is non-negotiable. To this end, disposable nurse gowns must adhere to strict guidelines.

Quality Assurance

Before being packaged and shipped, each gown is inspected. This rigorous quality check ensures not only protection but also comfort for the wearer. After all, medical professionals wear these for extended periods.

Future Trends

The medical industry, like all others, evolves. As we advance, what innovations can we anticipate?

Sustainable Alternatives

The spotlight on climate change has led to a surge in sustainable alternatives. Manufacturers are researching and implementing methods to reduce environmental impact without compromising on safety.

Biodegradable Materials

The dream? Gowns that serve their purpose and then return to the earth. Biodegradable materials, already making waves in other industries, are being tested for their viability in nurse gowns. This approach promises a future with reduced medical waste.

Conclusion

From raw materials to the finalized protective gear, the journey of a disposable nurse gown is laden with innovation, rigorous checks, and an eye on the future. As the industry progresses, the balance between safety, comfort, and environmental consciousness will continue to shape its trajectory.

FAQs

- What’s the primary material used in disposable nurse gowns?

- Polypropylene is predominantly used due to its combination of durability and lightweight properties.

- How are sustainable materials changing the landscape of disposable gowns?

- They’re ushering in an era where safety and environmental responsibility coexist, with biodegradable options at the forefront.

- How do manufacturers ensure the sterility of each gown?

- Gowns undergo stringent sterilization processes, such as autoclaving and ethylene oxide treatments, before being deemed fit for medical use.

- Why is quality assurance crucial in gown manufacturing?

- It guarantees that each gown meets the safety standards and ensures the comfort of medical professionals wearing them for extended durations.

- Are there international standards for nurse gowns?

- Yes, organizations like ISO and ASTM set global standards that manufacturers must adhere to, ensuring consistent quality across the board.